Compass Software Acquisition by SEMA & Ludger Ostendarp Proclaimed 2. CEO

Compass Software announces its acquisition by the SEMA Group. As part of the merger, Ludger Ostendarp has been appointed second CEO of Compass Software GmbH alongside Lukas Hollinderbaeumer.

The SEMA Group is the world's leading provider of CAD/CAM software in the fields of timber construction, stair design and sheet metal work.

The merger of the two companies sends a strong signal to the construction industry. The combined innovative power of both teams will create significant added value for the customers of both companies.

Lukas Hollinderbaeumer becomes new CEO

Compass Software celebrated its 30-year anniversary in 2022 and took this occasion as a chance for a generational change at the company. Lukas Hollinderbaeumer was appointed as the 2. executive director next to Detlef Hollinderbaeumer in June 2022. Lukas had already gained extensive experience as Compass Software’s head of project management and as a member of the extended executive management team. Since the death of our longstanding CEO Detlef Hollinderbaeumer in July 2022, Lukas has been leading Compass Software as the sole CEO confidently into a new future.

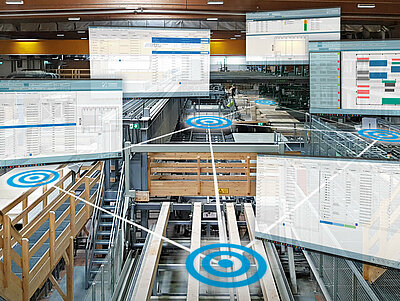

Manufacturing Execution System – MES

Our PROKON module for production management and control has been extended to become a complete MES software. The manufacturing execution system is used for the organization, control, and management of all production, no matter the size and degree of automation. The MES solution can be used in all industries, such as stair building, timber construction, CLT manufacturing, and more.

Find out more here.

Production Management and Control

The module production management and control (PROKON) was developed as a solution for production organization, management, and control of all sizes and different degrees of automation. PROKON connects seamslessly to our stair building and timber solutions. Furthermore, it is possible to implement PROKON in connection with external systems at any step during production. In the field of automation, PROKON can be connected with different systems, such as machines, robots, cranes, or other conveyor technology.

Some of the most important advantages:

- Digitalisation, interconnection, and control of all production processed in real-time

- Fast respond times and flexibility for short-notice orders

- Reduction of lead times and fast delivery on all orders

- Paperless production

- Partial or full automation possible

- Scalable to every size and production method

- Only one integrated software, which can be connected and synchronized directly with an ERP-system.

Established Office in South Germany

The new Compass Software office in Bad Endorf ensures a reliable presence in the southern region. The new branch enables CS to react faster to requests for timber and stair building software in Southern Germany, Austria, and the surrounding regions.

The southern branch is managed by Lukas Hollinderbaeumer, and plays an integral part in answering the growing number of requests for large projects in the woodworing sector.

Project Launch Cross Laminated Timber Processing

Cross-laminated timber (CLT) is considered the material of the future by building experts around the world. However, the processing of cross-laminated timber on CNC machines poses several challenges that need to be overcome. The sheer massive size of the CLT boards is a problem in itself. Manufacturers have to control special machines that offer the necessary range of motion. Once, plates are positioned on the machine, it is not easy to move them again, due to their weight and size. In practical terms: CNC programs have to be extremely precise and need to be adjusted for each individual case. Compass Software is able to configure CNC data optimally in relation to the machine and the individual customer. Location-specific CNC programs make CLT production possible. The CLT solution from Compass Software imports CAD information from all common construction software in BTL format. All established machines on the timber market can be controlled and Compass Software customers are assured that they can confidently overcome all challenges CLT processing present.

Application of Virtual and Augmented Reality

Compass Software is known for its innovation and utilising new technologies. Thus, it was important to us from the start to tap into the full potential of new developments, such as virtual and augmented reality. Our virtual reality solutions lets users create entire room situations in the virtual space. This tool is especially interesting for sales purposes in the stair building sector.

After the development of our virtual reality solution, Compass Software presented its augmented reality application for the first time at the LIGNA 2017. We utilise the Microsoft HoloLens to make the AR technology possible. When using the AR glasses, the user is able to see his or her real surroundings and at the same time it is possible to project virtual elements, e.g. staircases, into this reality. The AR glasses are an immense help for sales, since customers are able to see the virtual staircase in the actual room. Furthermore, the visualisation helps to avoid construction mistakes at an early stage.

New Corporate Design for Compass Software

“Change is a necessary part of life. Without change there can be no progress and improvement,” - Detlef Hollinderbaeumer, CEO.

Compass Software's trademark was left unchanged for almost 25 years. It was time to rejuvenate the logo. Of course the intend was not a complete rebranding, therefore, a more modern and fresh look was chosen, while the value of brand recognition remained. The company name remained an integral part of the logo. The entire appearance of the brand Compass Software became more distinct, modern, and concise.

Founding Compass Software Inc.

After more than 25 years of trying to manage sales in the US through dealers, CS has now committed to take more hands-on action.

We founded

Compass Software Inc.

in Atlanta, Georgia.

Processing of Joinery Elements Including Our BTL-Viewer

We met the company Krüsi from Switzerland and a new idea emerged. The vision was to develop an entire CNC processor, which would process joinery elements on machines designed solely for this purpose.

Out of this project grew an entire system that not only makes it possible to process data from timber construction programs for CNC processing during the preparation phase, but also contains a module which allows for this to happen directly on the machine. This requires a specially designed interface.

Additionally, we integrated a complete baluster optimisation, as well as a BTL-Viewer.

Processing of Window Components

Out of our collaboration in the field of sunroom construction another CNC-module for the processing of window components emerged.

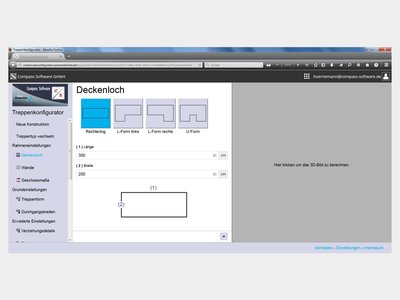

Designing and Calculating Staircases Online

As a result of the first major internet hype during the late 90s and early 2000s it was already decided that the staircase manufacturing software had to be compatible with the internet. But, contrary to the then predominant opinion, technology was nowhere near ready for "useful" applications.

Still, the computer scientists at Compass Software GmbH were convinced that technology would be ready one day and that they had to prepare for that day.

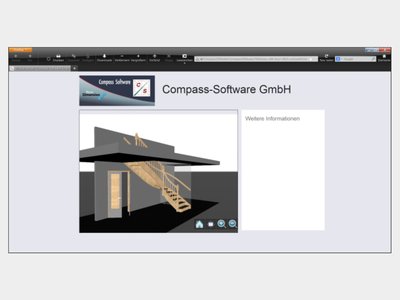

The entire development of the SSP ND (Version 10 of the staircase manufacturing software program, New Dimension) was geared towards this goal.

Otherwise, it would not be possible to run the software as a "black box" - as a calculator so to speak - on a server, which is hosted on the cloud, which, with the help of new user interfaces, enables users to design and automatically calculate staircases online using standard browsers, today.

For more information go to …

Furthermore, it is also possible today to upload any designed staircase or stairwell onto the server on the internet from where it can be visualised via a link.

For more information go to …

5 Axis Processing of Sunroom Components

Compass Software GmbH´s staff had grown an enormous amount of know-how when it comes to the connection of CNC machines during the last 30 years and more. More than 900 CNC connections with machines from more than 30 different suppliers with 2-5 controlled axes, or even more, have been conducted during this time.

This know-how had to be used more broadly!

The demand existed. CS developed a CNC connection for the 5 axis processing of sunroom components for another major German software company in the timber sector.

This product line is currently very popular on the Chinese market.

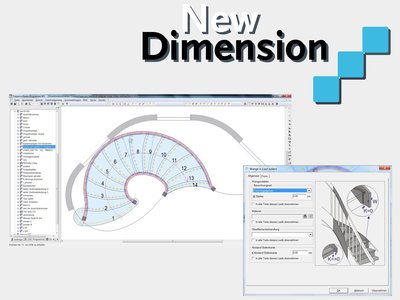

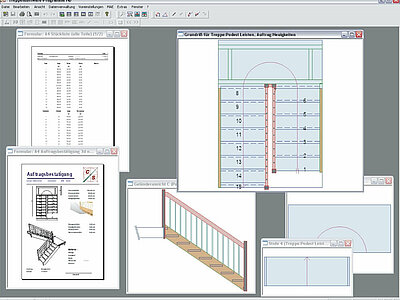

Version ND with a Complete Graphical Interface and Help System

Version ND (New Dimension) is the result of the systematic continuation of the development, which had started with Version 9. ND has a complete graphical interface with a graphical help system, which was a unique feature at that time.

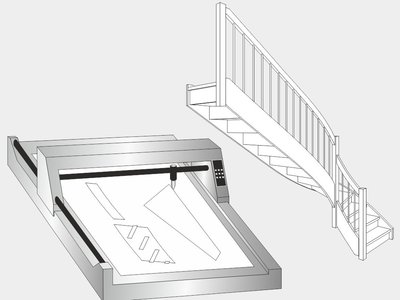

Fully Automatic Processing Including Automatic Loading

During this time a new phase in automation started, which has not been completed yet. This regards the fully automated manufacturing of staircase components and includes the automated loading of machines.

This development started with loading portals on automated tread machines like the ones mentioned above. Another step was taken with the development of a fully automated post machine, in collaboration with the company MKM. Stair builders were able to load the machine with posts in an arbitrary order. Every post had to be scanned with a barcode reader and the software sorted them into a queue, which was then processed automatically during unmanned production.

For further milestones see …

Handrail Wreaths with Profile Cutters

This is one of the most important developments CS has ever conducted. One of the biggest challenges in staircase manufacturing is the production of curved profiled handrail parts.

Due to the geometry of these parts it is mathematically challenging to calculate a corresponding model in order to automate the processing on a CNC machine with 5 axes.

Especially transitions between curved and straight parts are impossible to describe with closed mathematical models. Thus, the developmental period became relatively long. Testing on a machine, to validate the theoretical calculations, were necessary again and again.

The fruit of this labor was presented to the public in 2001 and is still setting the standard today.

It took several years before the competition was able to produce an even rudimentally acceptable result.

Production of staircases on machines with 5 axis technology without this module has become unthinkable today.

Network-Compatible Client/Server Software

In 1998, the foundation for the contemporary staircase design software structures was laid. After an intense period of research and planning, CS decided to take a completely new path. It was decided to develop client/server software, which would be entirely network-compatible. The basis would be an object-oriented data base, which would contain all of the system´s data. Development is always conducted with the latest tools and software technology.

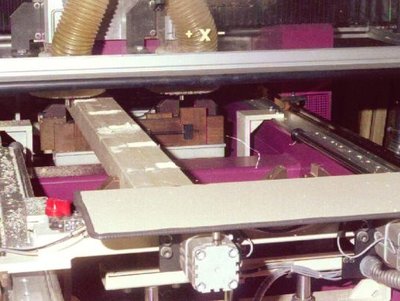

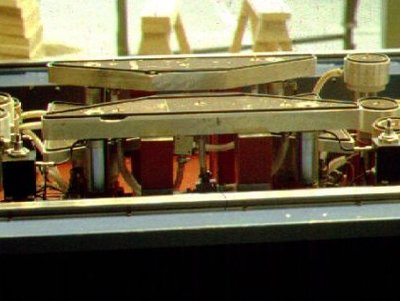

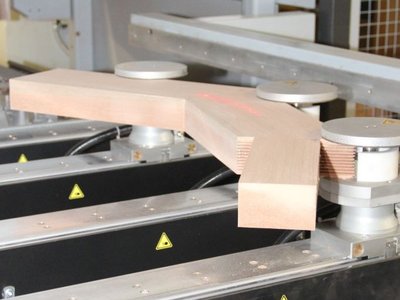

Automatic Vacuum Cup Positioning - Barcode Scanning

It was during this time that the first special-purpose machines were developed and the first machines with automated vacuum cup positioning were brought into service. Again, CS was a leading contributor to the developments in this sector. Right away, these machines were controlled by CS in such a way that the customer did not have anything to do with their programming.

The developments back then laid the foundation for the systems that control automated vacuum cup tables today. Back then, they were only used for tread processing and post machine. Today, CS is able to control any system existing on the market, be it a pin table or a joist-system with mobile vacuum cups and clamps. The components can even moved during production now.

Additionally, the first machines with barcode readers, which are fully integrated into the staircase software, were equipped at that time. This made it possible to launch and control the entire process for loading and starting the machine with a barcode reader. The result is an enormous amount of time saved, plus the possibility for errors is minimised.

Founding of Today's Compass Software GmbH - Exclusively Software for Staircase Manufacturing

In 1992, after experiencing some turbulence, today´s Compass Software GmbH was founded. It was decided that the company would exclusively develop, sell, and maintain software for staircase manufacturing.

This decision proved successful and the strategy was maintained approximately until the year 2010 (more about this later).

The decision was also right for another reason; the "roaring 90s" had started. Due to the reunification of Germany, there was a major special business cycle in the building sector. East Germany was in a gold-rush mood. Even though many of the then new customers have disappeared by now, CS still maintains long and fruitful customer relationships with many excellent customers there.

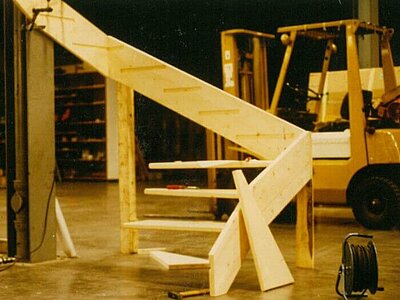

Processing Wreaths on 5 Axis Machines

The possibility to process stringer wreaths on machines with 5 axes was "simply" added, just because it seemed so natural!

The complete software/machine system was then presented to the public at large for the first time at the Ligna 1987.

The first machine with 5 axes that was controlled directly by CS.

3-Dimensional Visualisation

The design software sector experienced rapid developments, parallel to the CNC related advancements. Due to the exponentially improved performance of hardware (PCs) each year, we were able to continually make the software work more efficiently and it became more and more applicable.

It was then that Detlef Hollinderbaeumer developed the first integrated three-dimensional display of staircases on a computer. Back in 1986 it was all about leveling off 3D-drawings on pen plotters, that is to say, the system was vector-based. Thus, it was already possible to scale drawings to every size, without losses.

Today, 3D images are rendered pixel-orientated on devices.

This technology was added later by Ludger Ostendarp.

Development of 5 Axis Technology

In 1986 one stair builder approached CS and MAKA with the request to mill risers angled into the stringer on a CNC machine. This is only possible if the cutter is able to work exactly into the direction in which the riser is going to be inserted into the stringer.

This requires 5 axis technology.

A 27 year old computer scientist does not deem anything impossible, as he feels "invincible." Therefore, it was decided: "We are going to do it!" The groundwork for an unprecedented development was laid.

First International Machine Connection

Word that the system was working got around fast. Since MAKA was active as an international company, there were inquiries from abroad straight away.

First machines were brought into service in France and Norway in 1985. When it came to development, CS was therefore compelled to keep an eye on both CNC technology, as well as staying internationally compatible. The latter does not only affect translatability and applicability, but also international structural differences for staircases.

Today, CS customers still benefit from this transfer of know-how that was passed around internationally!

The company COMPASS GmbH was founded in 1985, which was the predecessor of today´s Compass Software GmbH.

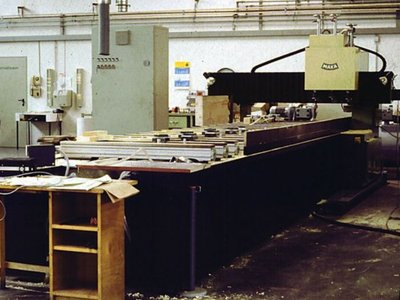

Connection of the First CNC Machine

As early as 1983, one customer requested the connection of a CNC machine for the production of wooden staircases.

The company Trautwein out of Weingarten, Germany had expressed great interested when they were contacted by the CNC company MAKA. Only a short time prior to this our computer scientists had approached MAKA and had co-developed the idea for a direct software connection to one of their CNC machines.

The concept was born, the automated transfer of manufacturing data from a design system directly to the machine.

Every staircase design software on the market has been guided by this idea ever since (to put it cautiously).

Finally, the first CNC connection was brought into service in 1984.

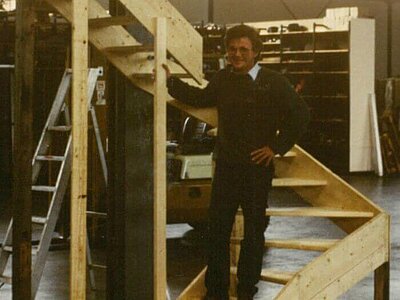

Startup More Than 30 Years Ago

Some of Compass Software GmbH´s (CS) most important software developers have been devoted to topics concerning software for staircase manufacturing for 30 years and more.

These are the computer scientists

Ludger Ostendarp

(today head of development and CEO at CS),

Manfred Hoernemann

(also leader at development at CS)

and

Detlef Hollinderbaeumer

(below on the staircase 1.0),

who joined the team in reverse order during the 80s.

In 1982 a development started, which closely correlated with the technical advancements of the PC and application software in the field of woodworking and which has significantly influenced these fields.

CS is still benefiting from this head start and expertise today.