The offset table further automates production and eliminates errors and manual rework.

The offset table further automates production and eliminates errors and manual rework.

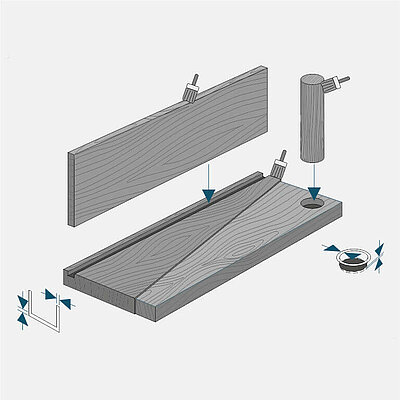

The use of different materials and surface treatments can cause the dimensions of parts and their mortises, pockets, and drillings to change after treatment. To ensure that all parts fit together accurately, the offset must be known in advance so that all mortises/drillings, etc. can be milled to fit.

In addition to the CNC predefinition, the feed table and the vacuum cup predefinitions, Compass Software allows you to define an offset table. This table defines offsets based on the materials and finishes used, which are then automatically added to mortises, pockets, and drillings.

Using the information in the offset table, the system automatically knows how much addition is required for each material/surface treatment and adjusts the operation accordingly.

Once the table is set up correctly, there is no need for manual entry, eliminating errors that can occur due to forgotten entries or overriding machine settings.

In addition, there are now categories for different materials and surface treatments where the user can specify how absorbent the material is or how thick the coating is. When creating the CNC program, it is possible to activate a warning to indicate which offset, if any, should be used for the machining. This warning will appear in the CNC creation log.

This further automates the processing of stringers, posts, handrails, treads, top rails, bottom rails and base rails.

This option can be purchased separately.

Is this the option you have been looking for to optimise your next stair construction project?

If so, contact us now, we would be happy to assist you!