General

External Stair: Copy Risers

In the external staircase, there was a "copy" function in the order tree on the individual treads. This was not previously requested for the risers. At the request of a customer, this feature has been added to the risers as well.

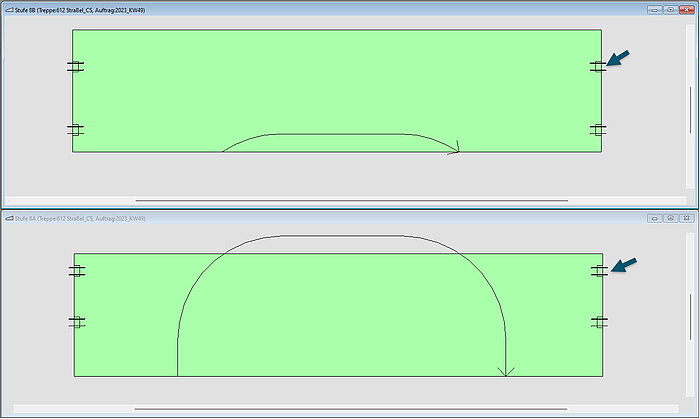

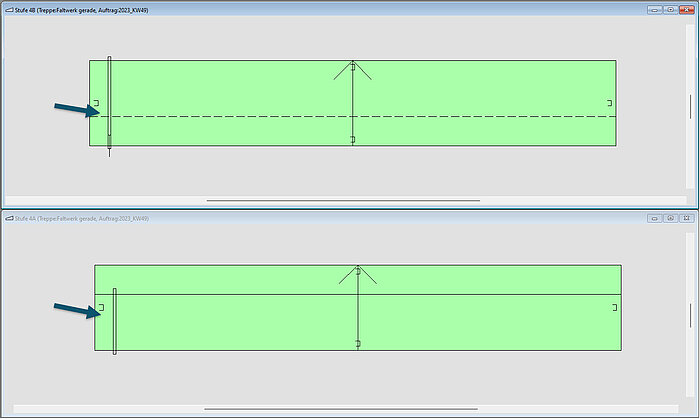

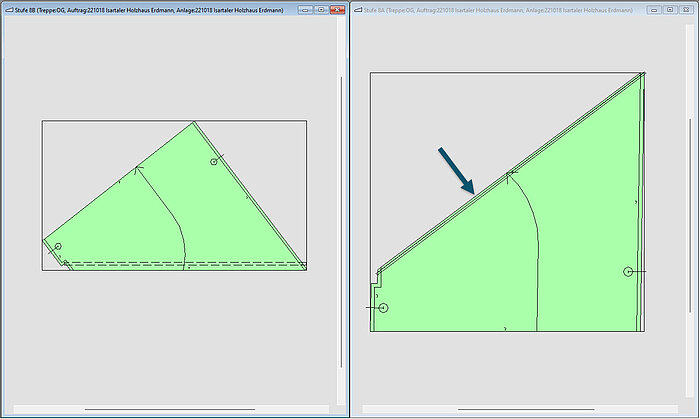

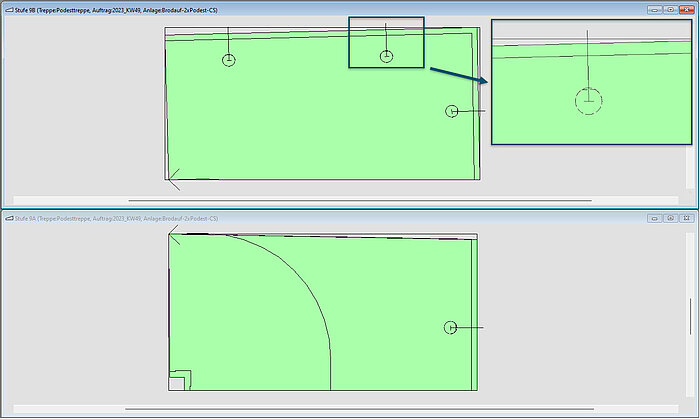

“Split” Landings and Treads in the Order Tree

Treads and landings can be split into two or more parts in the order tree using the "Split" function.Previously, some operations were not considered in the "split" function. Due to the increasing number of customer requests in this area, we have collected the open requests and revised the function.

The following functions have been updated:

- The riser grooves on the rear edges of the treads remain intact after cutting.

- The glass grooves in the top edges of the treads remain intact after cutting.

- Pockets on double angles remain intact after cutting.

- Riser grooves in arches remain intact after cutting.

- The flattened pockets of the clamping screw remain intact after cutting.

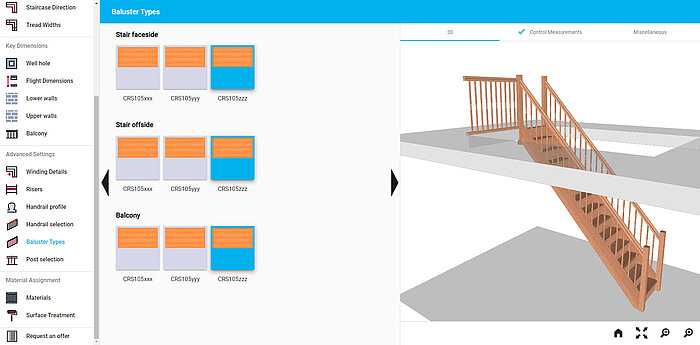

Balcony Railing Balusters in Online Configurator

In the initial online calculation, the balcony is now calculated using the standard baluster specified for the staircase. Previously, in the Stair Configurator, as in the offline system, the baluster type came from the balcony predefinition. This was often different from what was required online.

Online, the baluster type defined by default in the Stair Configurator administration is now used in the initial calculation of the balcony balustrade.

It is now possible to change the baluster types separately in the railings.

Export Article List, Labour Cost and Installation Cost Lists

When exporting a staircase in CS format, previously only the assigned items, labour costs and installation costs were exported. We have extended this function. Now active article lists, labour cost lists and installation cost lists including their content are also exported.

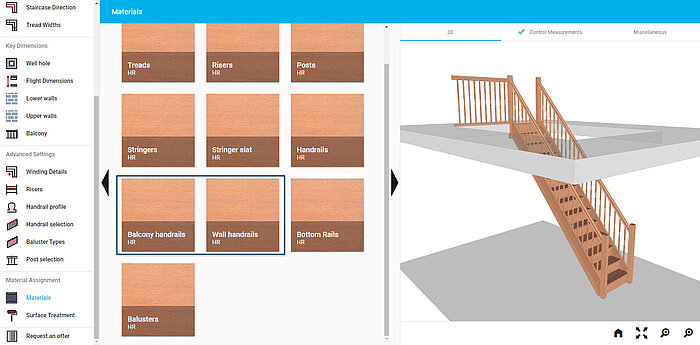

Stair Configurator Different Materials for Handrailing

In the Staircase Configurator, the material and surface for the wall handrail and the balustrade handrail can be set separately from the rising handrail. The initial calculation follows the settings made by the user in the management of the staircase configurator in the basic system.

Export and Import of Material and Surface Treatment of Cuboids

The material and surface treatment of a cuboid are now also exported when exporting a staircase to a CS file. The data are also considered for the import.

Check File Name for Invalid Characters

The file name for the export can be set in the DXF CAM export. Not all characters are allowed in file names. Previously, the system did not check whether the file name was valid, which caused problems during export if the name was invalid.

This has been extended:

- A new input with invalid characters for file names is no longer possible-->the dialogue cannot be exited with OK, a message informs the user about the problem.

- If characters should have been forgotten or settings with invalid characters already exist, the invalid characters are replaced by underscores. This means that the export can always take place.

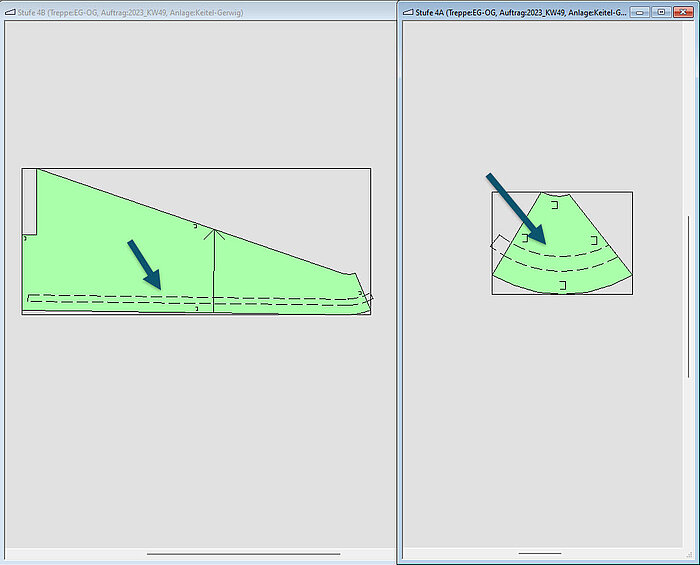

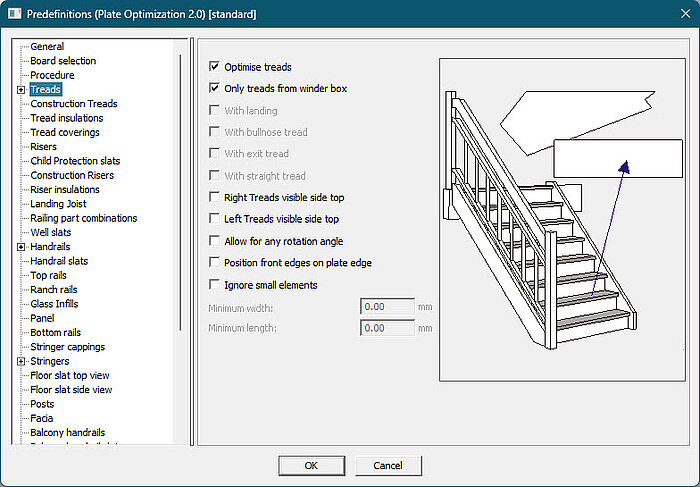

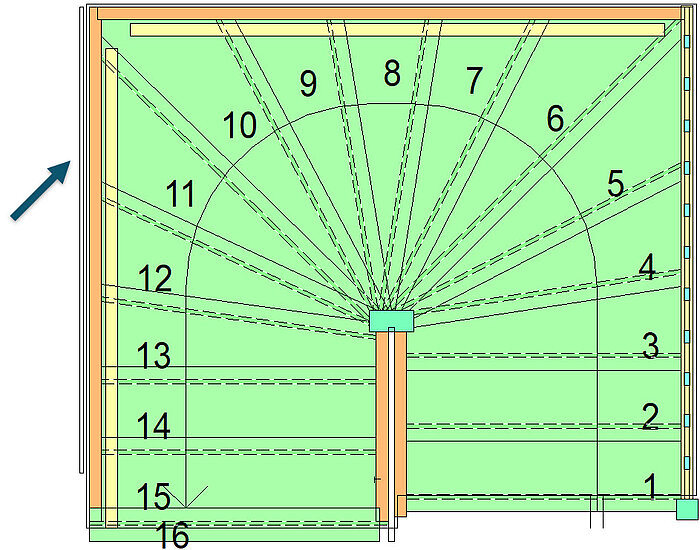

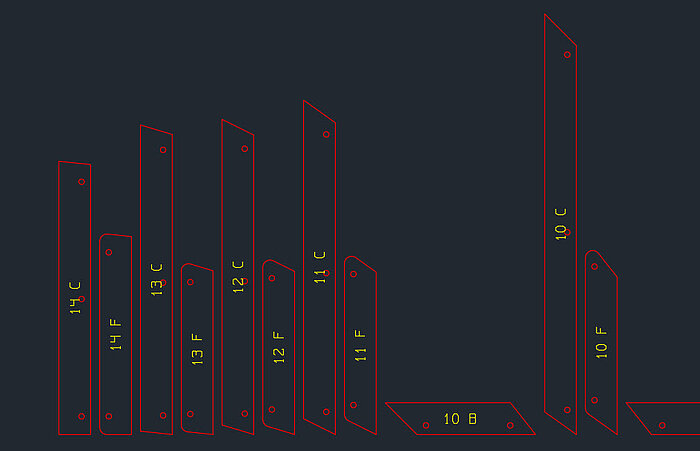

Plate Optimization 2.0: Winderboxes

In the Plate Optimisation 2.0, the function ‘Only steps from the Winderbox’ was added for the treads. Herewith, custumers, especially those in England and America, have the possibility to optimise only the winderbox treads in the nesting plate during nesting.

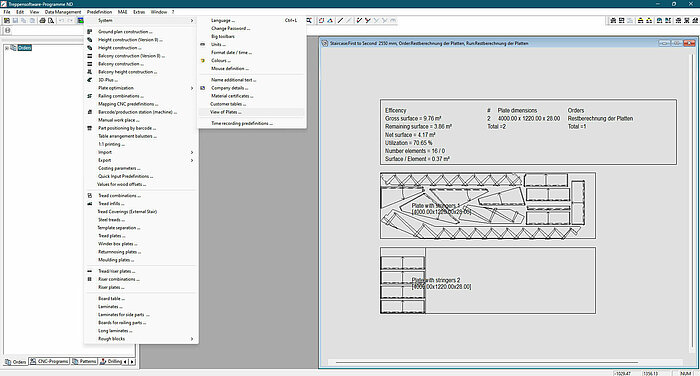

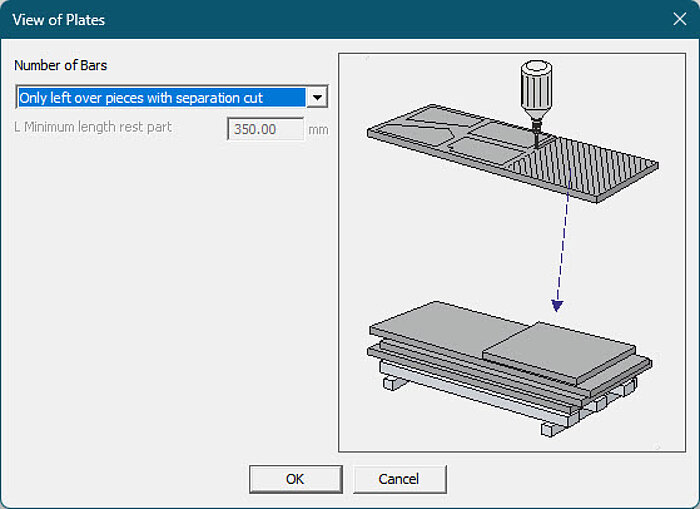

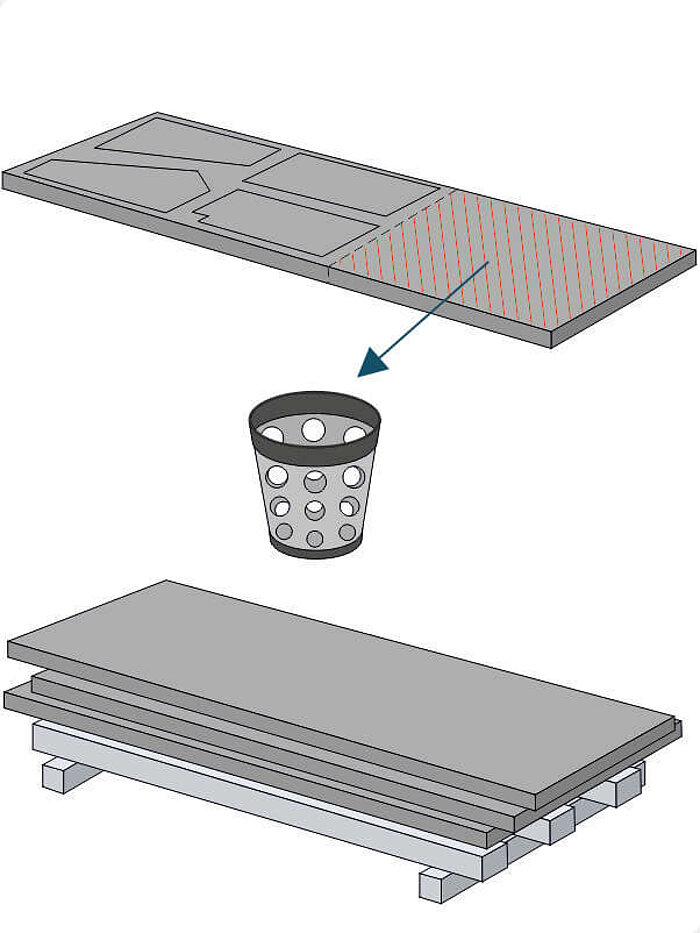

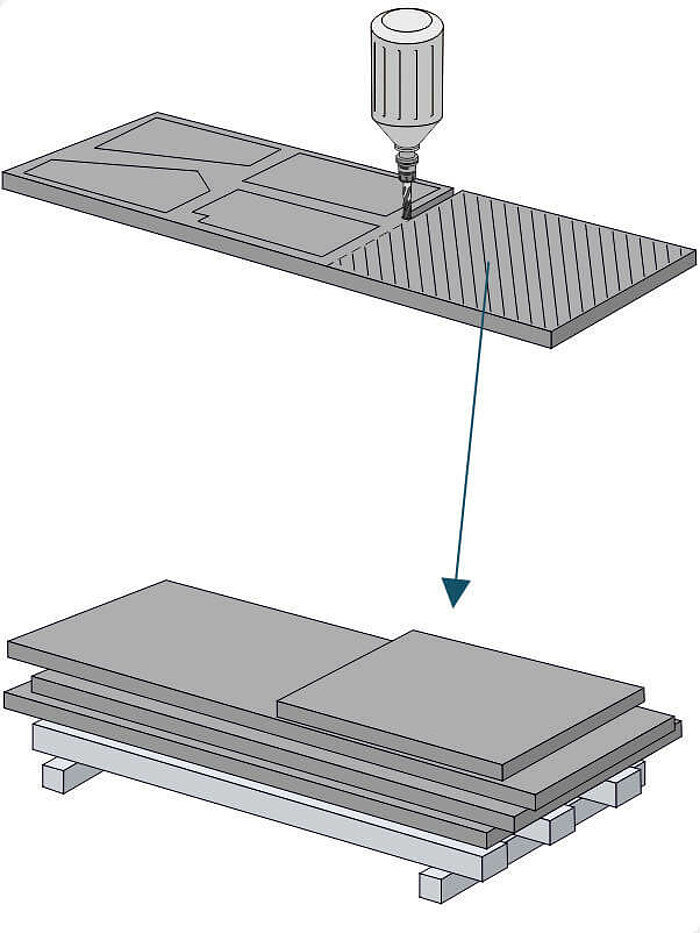

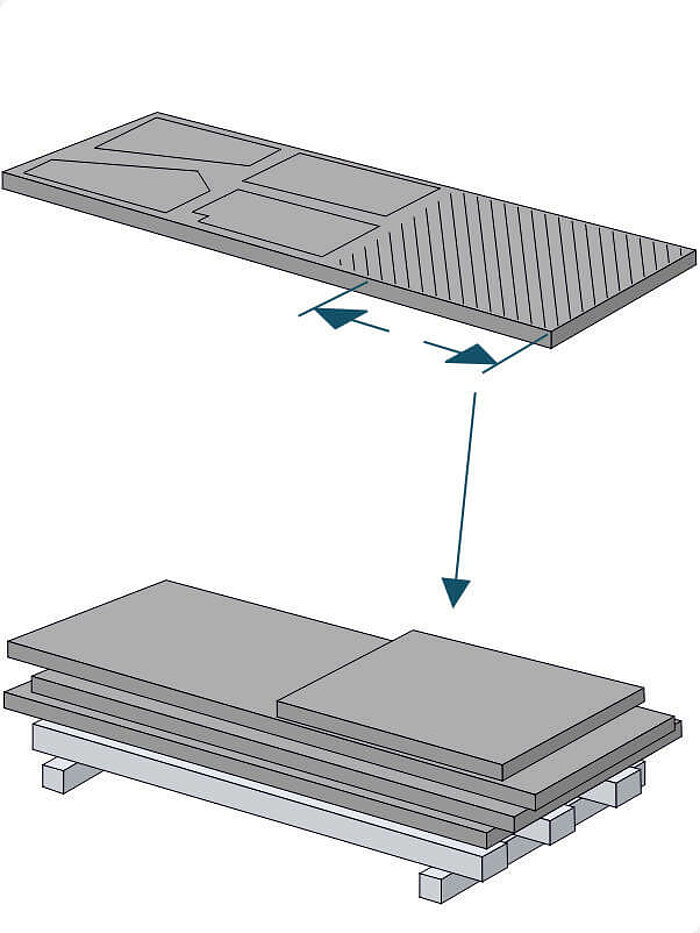

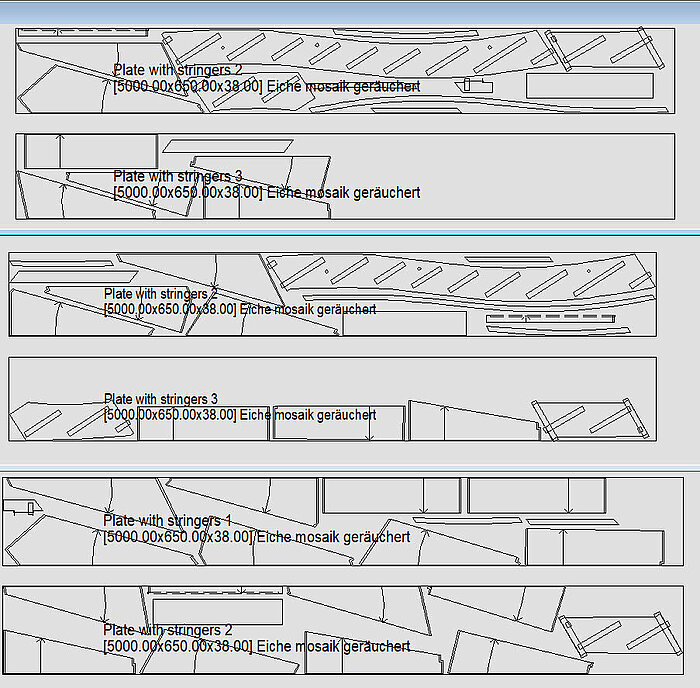

View of Nesting Plate Utilisation

There are now three different ways to view the usage of nested plates.

Double-clicking on production parts in the tree of orders opens all nested plates, and the plate efficiency and plate size/number are displayed above the plate display.

The efficiency calculation can be customised by the customer to suit their production requirements.

Three variants are available:

- Everything is waste.

- Remaining pieces are good parts - with the option to enter a minimum size.

- Only left over pieces with separation cut - the separation cut is defined in the plate calculation.

The user can now better determine how the nesting plate utilisation should be calculated.

This feature will be available in the next release version.

It is also possible to arrange parts even more individually in Plate Optimisation 2.0. You can find out more here.

CTRL+A "select all"

In the table views, the Windows shortcut CTRL+A for "select all" has been extended. Now, this should work in all tables.

Here is a list of the tables:

- Board tables

- Plate optimisation 2.0 part selection and board selection

>> Table entries under the Data management menu - see image.

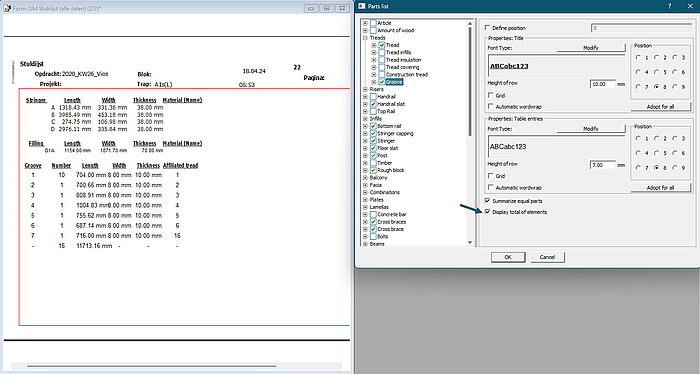

Automatically Adding the Total Length of Rubber Grooves in Parts Lists

In the parts lists, it is now possible to automatically add the lengths of the rubber grooves using the " Display Total " function.

In some markets, such as the Netherlands, rubber inserts are very popular as anti-slip protection for treads. The rubber inserts are installed on site. They are delivered on large rolls. With the new function, the required total length per staircase can now be accurately calculated in the parts list. This simplifies the ordering of accessories and avoids that too little anti-slip rubber arrives on site or that unnecessary extra material is prepared in the workshop.

Stair Design

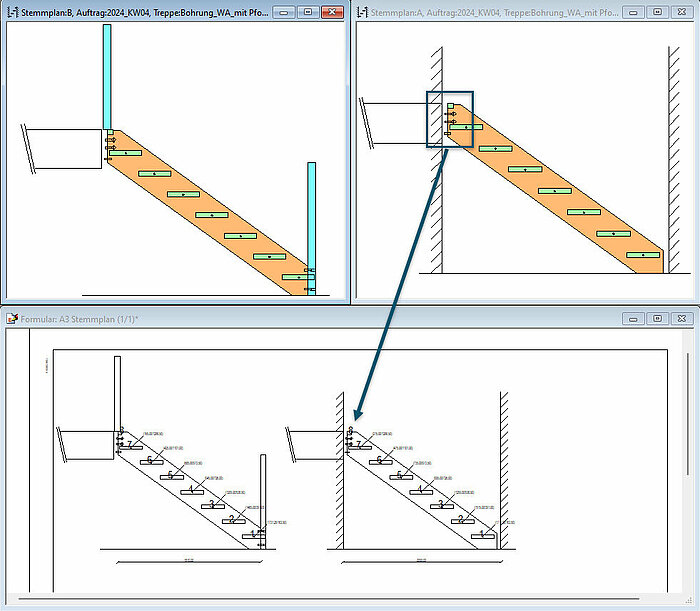

Drilling Pattern Stringer Wall/Ceiling

The front is now transferred into the displays in the tree of orders and the form mortising plans.

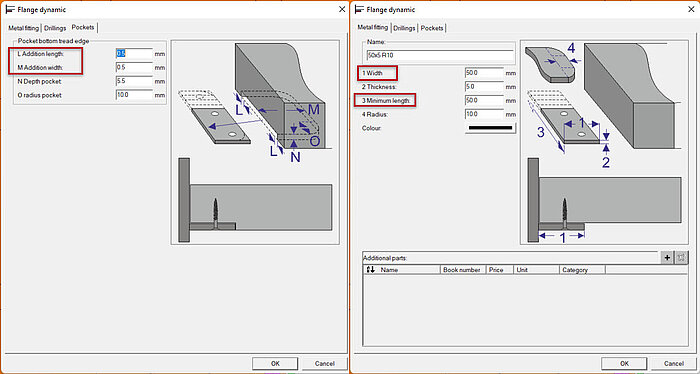

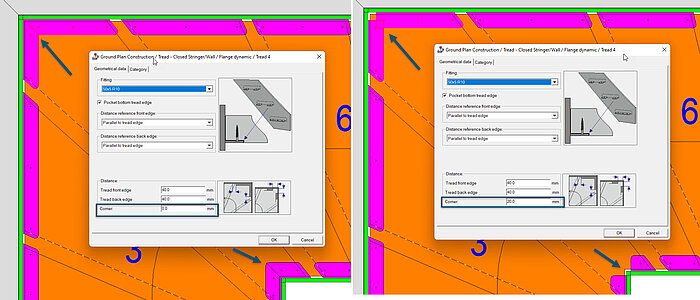

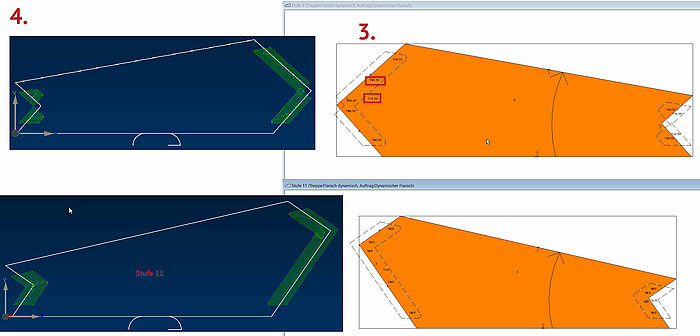

Dynamic Flange

The dynamic flange has been modified and optimized as part of the expansion.

- The parameters for the pocket settings have been corrected, length is width, width is length and it is possible to work with additions.

- In the outside or inside corners, only the distance to the corner is taken into account; if zero, a miter is calculated; if greater than zero, 90° is output.

- For the pockets in the tread, the additions from the dialog are taken into account.

- If possible, the pockets in the template are combined into one pocket.

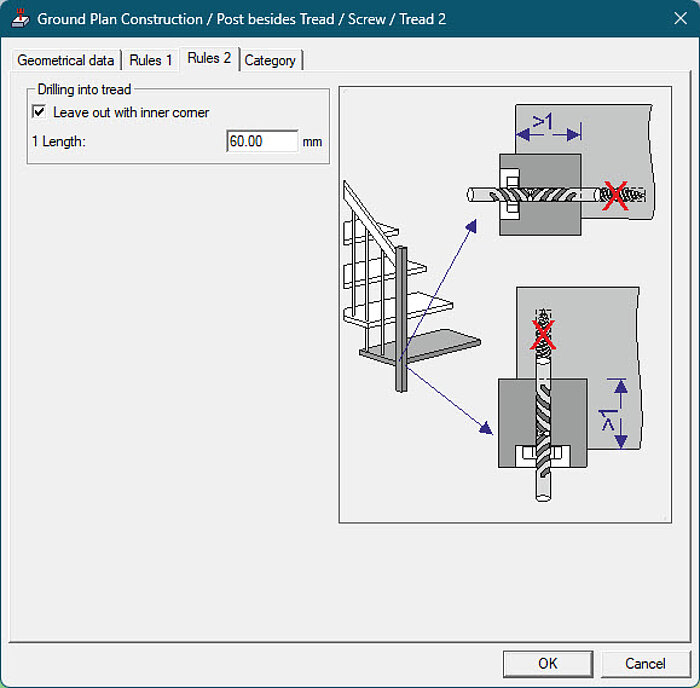

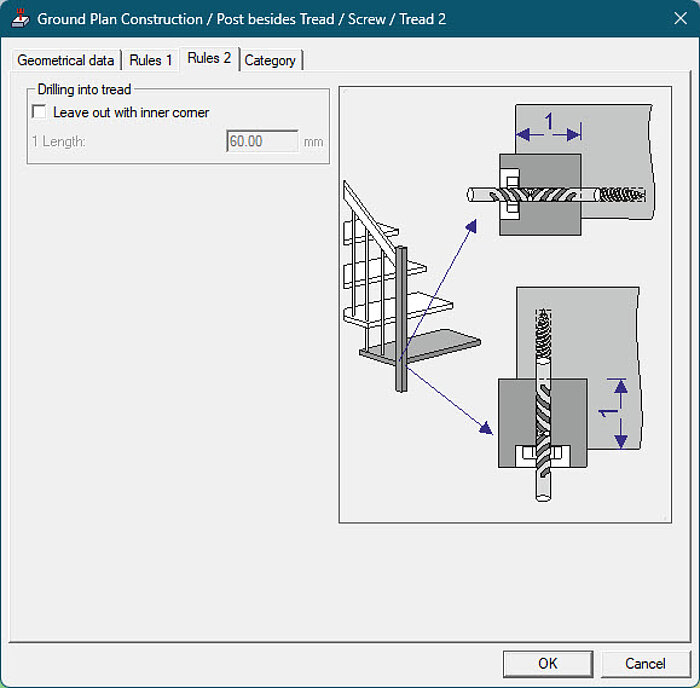

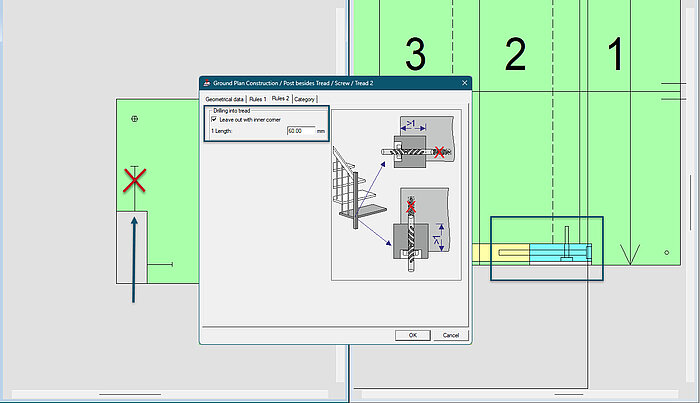

Drilling Pattern Post besides Tread

A rule has been added to the drilling pattern post besides tread. It is now possible to suppress drilling in the tread template. The length of the inside corner that causes the post in the template is checked. If this corner is longer in the drilling direction than the set value, the drilling in the tread is suppressed and must be done manually. The post drilling remains in the desired position.

Application: e.g. the flat post of a handrail-supporting bolted staircase as shown in the picture below. Standard dimensions approx. 160x45 mm. This post is connected to the tread with thick, long system screws. The system screws must be pre-drilled.

Problem solved: The drilling depth and the length of the inside corner, which can vary depending on the system and structural conditions, cause problems with the tool length. If the drill bit is too short, the tool holder or even the power unit will move into the edge of the material during drilling. The material is broken and in some cases the tool and machine are damaged. This can now be prevented, justifying the extra effort for the customer to drill the hole in the tread by hand.

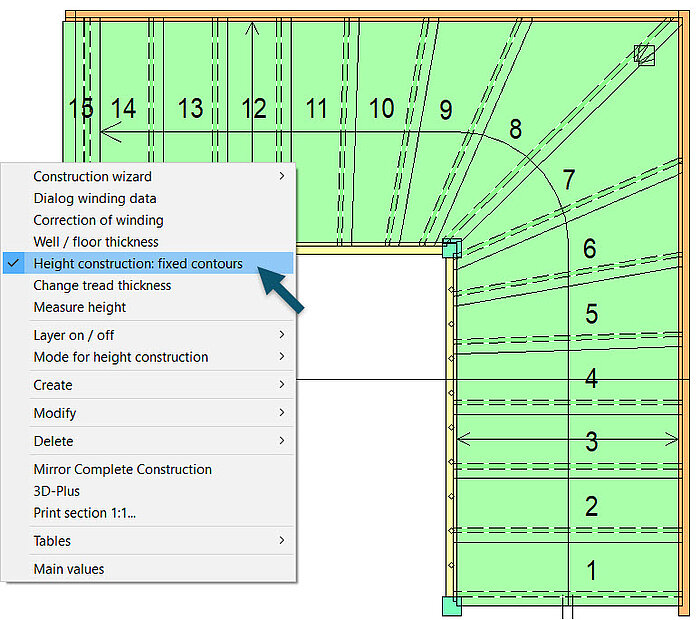

New: "Freeze" Height Construction

In Compass Software, it is now possible to freeze the height construction so that the run parts remain unchanged when modifications are made to the floor plan.

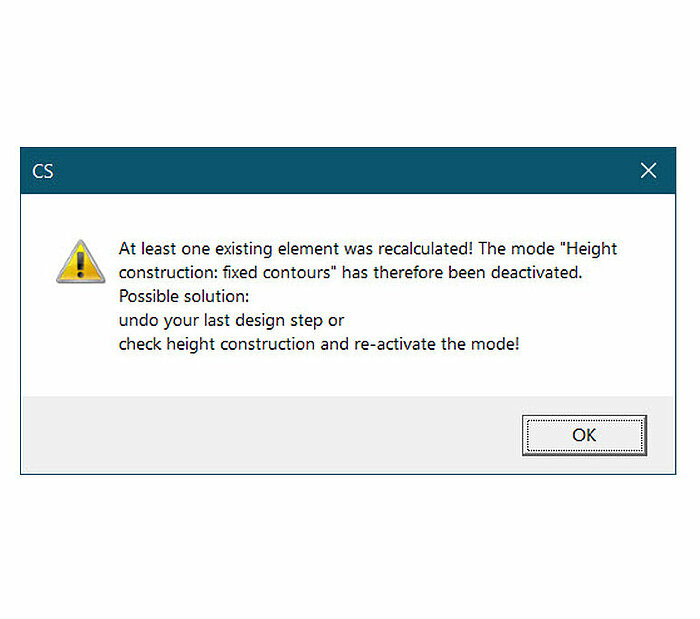

It is possible to freeze the contours of the height construction in the floor plan construction. When this mode is enabled, the contours of the run parts remain unchanged until the run part lengths are changed and a recalculation is required. If a recalculation is unavoidable, a warning message is displayed, and the mode is disabled. The mode can then be reactivated.

The following floor plan actions do not trigger a recalculation, as the run length remains the same:

- Creating a riser

- Changing riser thickness

- Changing tread thickness

- Changing tread overhang

- Rounding the front edge of the tread

- Creating block treads

- Creating child protection slats

- Changing baluster type

- Deleting infills

- Tread winding in the staircase, except at the entrance tread

The following actions in the floor plan trigger a recalculation as the run length changes:

- Creating posts

- Changing corner connection type for run parts in the floor plan

- Tread winding at the front edge of the entrance tread

- In general when creating infills and run parts (depending on situation: preserving the contours works for some actions)

- Changing infills (depending on situation: preserving the contours works for some actions)

- Changing run part thickness

- Changing handrails to round handrails

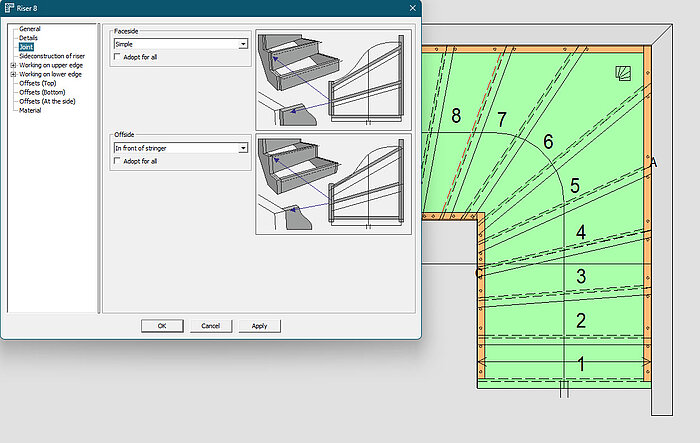

Risers Menu Side Construction Expanded by the ‘Adopt for all’ Function

For risers, the menu side construction has been expanded by the ‘Adopt for all’ function. If treads are cut at auxiliary lines, bullnose treads are created internally. So far, the risers had to be reset individually to ‘Follows bullnose tread’ for e.g. 15 risers. This was time-consuming and has now been significantly improved.

Import from Hartmann Steel Construction Software

The module external staircase can be used to import data from the Hartmann steel construction software. The treads are imported into the Compass programme with the correct contour. However, the internal edge identification generally did not consider the running direction.

Now, the running direction of the Hartmann file is imported as well. For the processing on the CNC machine the tread templates then also have the running direction-specific information for separate working operations faceside/offside and the corresponding feeds.

Export DXF Floor Plan Double Angles

The DXF floor plan export has been expanded by the display of double angles.

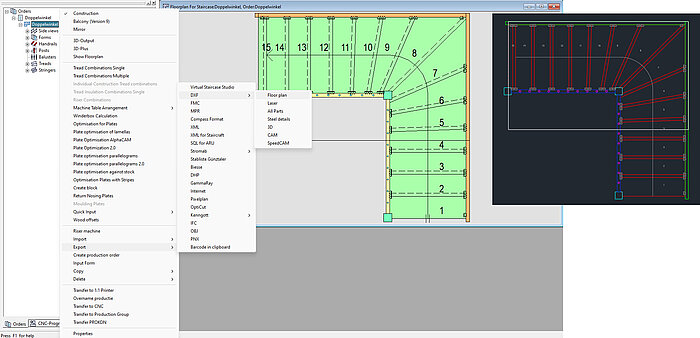

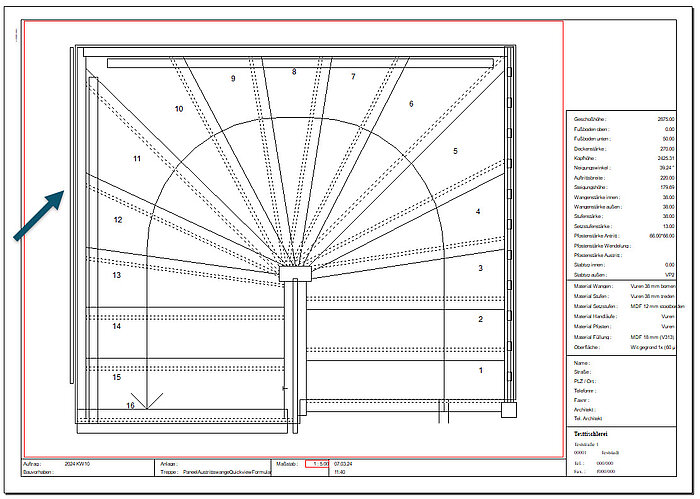

Forms: Panel on Top of Exit Stringer

The panel which lies on top of the exit stringer is now also displayed in the Quickview and in the form.

Front Panels Counter-Sunk Hole

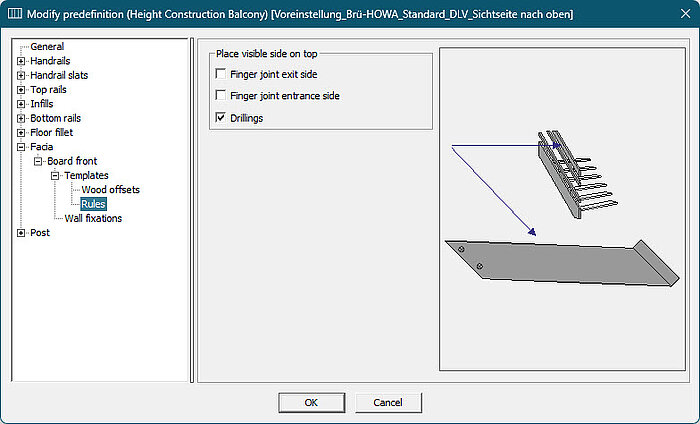

In the case of front panels, the conter-sunk hole of a drill hole was not taken into account so far when ‘Position visible side on top’ was chosen. If this is set by defaut, the front panel is now also rotated in case that it is useful for the processing of the counter-sunk hole.

Export dynamic Flange

In the DXF export of the steel details, the dynamic flanges are now labelled via an additional layer in the drawing. Previously, only the contours were exported. Now, all flanges can be clearly identified in the export. The flange contains the tread number and the identification of the stringer to which the flange must be welded. At the same time, these information are also added to the parts list form.

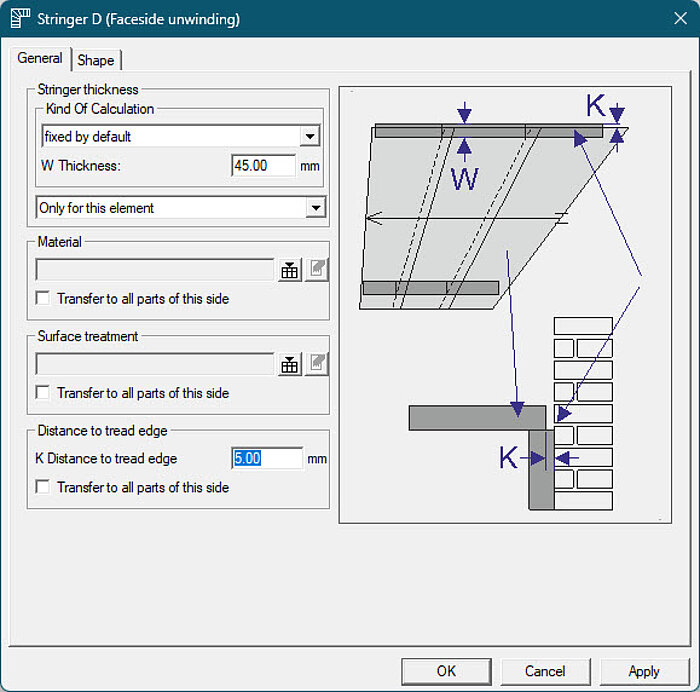

Extension Open Stringer with Shadow Gap

With Compass Software it is now possible to add a shadow gap to open stringers to create an assembly gap between the tread edge and the wall.

It is now possible to slide the open stringer over the visible tread edge to create a shadow gap between the wall and the tread edge. This is particularly useful for shaft staircases installed between two walls. With this type of stair, the walls are not always perfectly straight, and it can happen that the treads do not fit between the walls if the treads are made to fit exactly. To avoid this, a mounting gap is required. This is created using the Open Stringer with Shadow Gap option. The stringers can be screwed directly into the wall and the treads and risers can be fitted from above. The resulting shadow gap can later be concealed with a skirting board along the staircase.

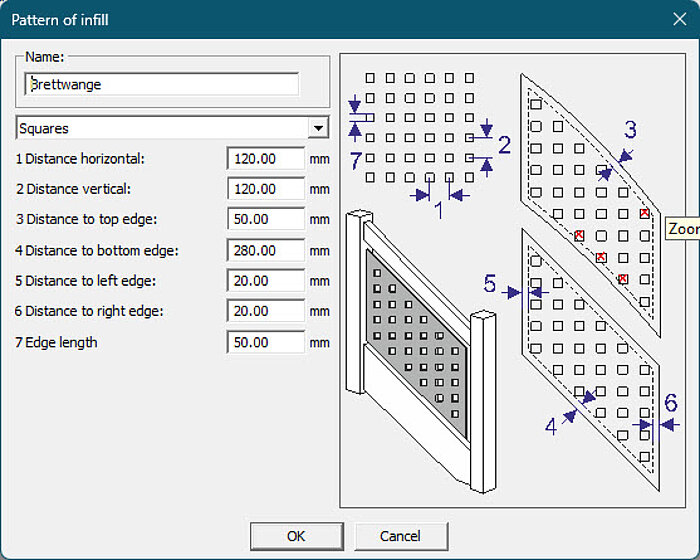

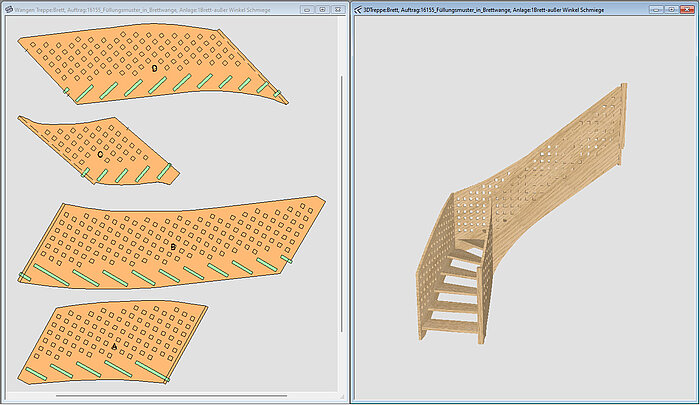

Extension of Panels and Glass Infills in Railings

The patterns for panels and glass infills in railings have been extended. The distance between the patterns and the four edges (top, bottom, left, and right) can now be defined individually.

This feature can now be used on board stringers, board stringers with handrails and mortised stringers. It is particularly suitable for decorating steel or HPL stringers. The stair can also be angled. The stringer corner joints "single top/bottom", "single continuous top + bottom" and "miter" are also supported.

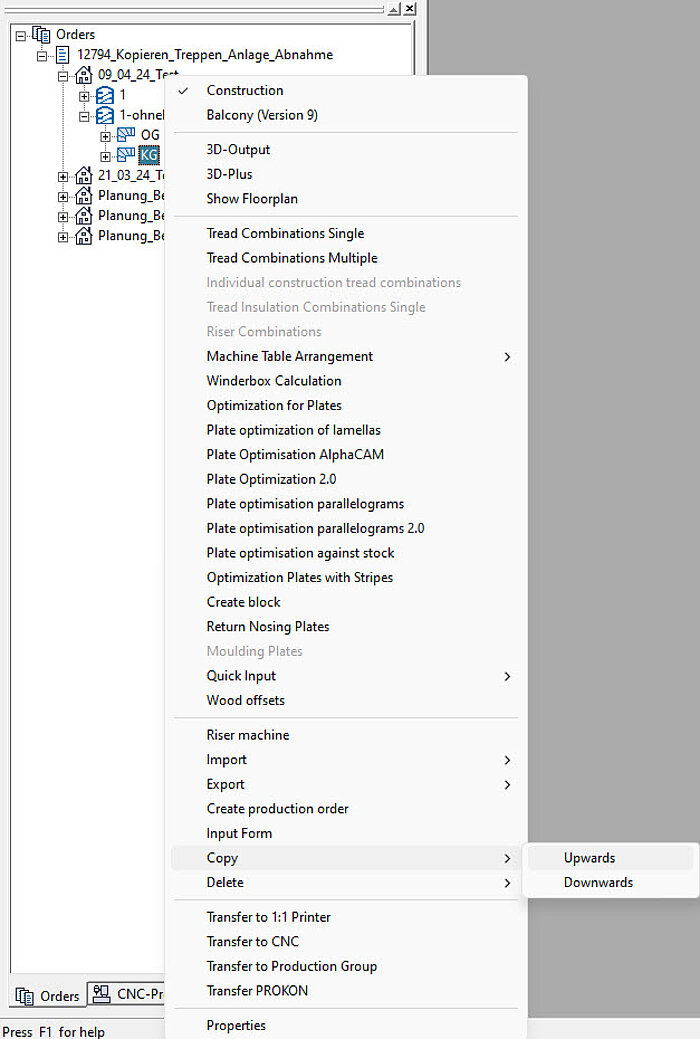

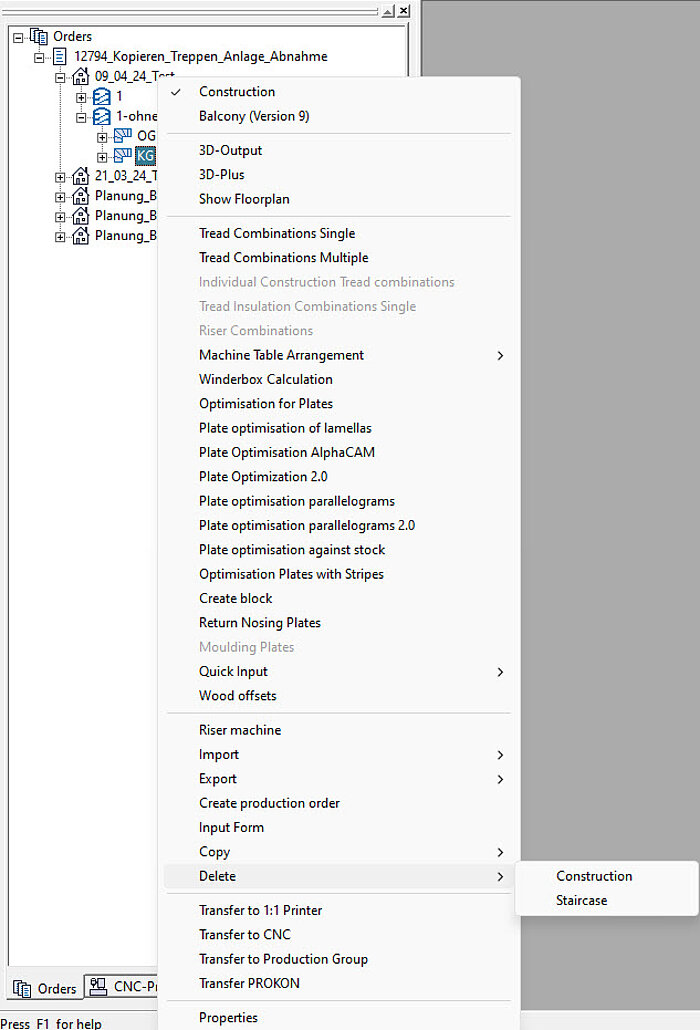

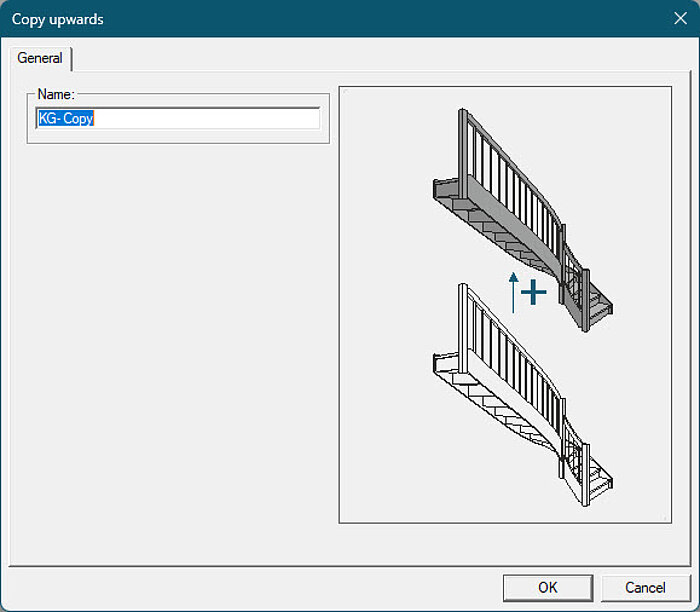

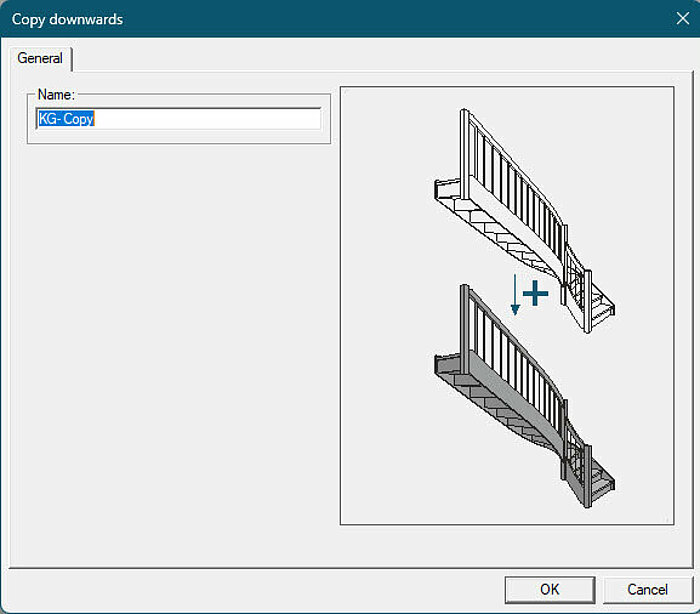

Copying and Deleting Stairs within a Run

It is now possible to copy and delete stairs within a run.

This feature saves a lot of time by eliminating the need to design identical stairs multiple times. In addition, it is easy to delete stairs that have been copied too many times by mistake.

In the order tree, the menu option "Copy --> Up" and "Copy --> Down" can be selected on a stair within a run. All data from the original stair will be copied, including the templates, the forms and the production parts.

Copying is only available for stairs without balconies. If a balcony is present, an error message will be displayed.

The function is included from CAD Staircase Basis and above.

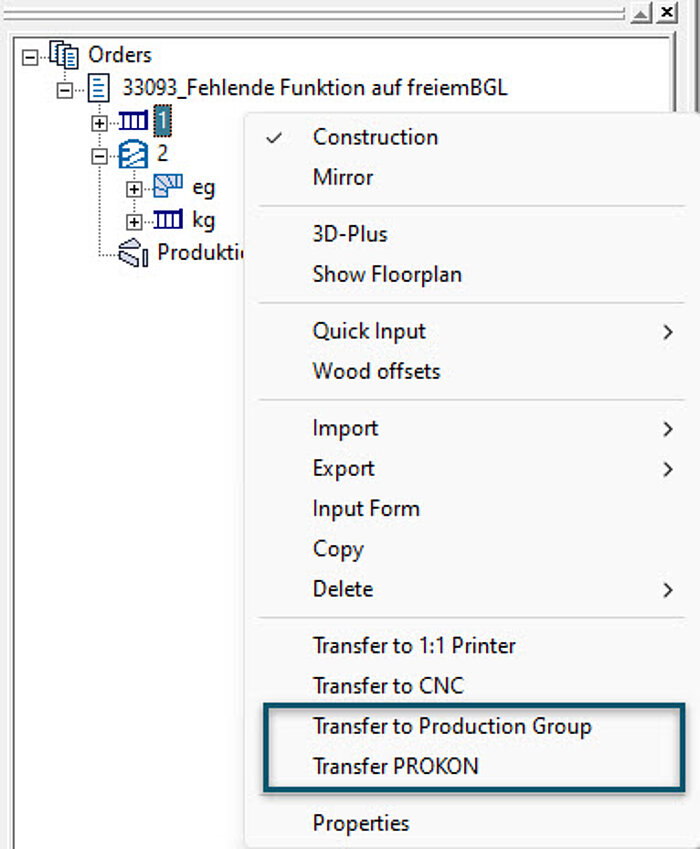

Transfer of PROKON for Balcony Railing

New feature: Transfer of production group and transfer of PROKON for balcony railing.

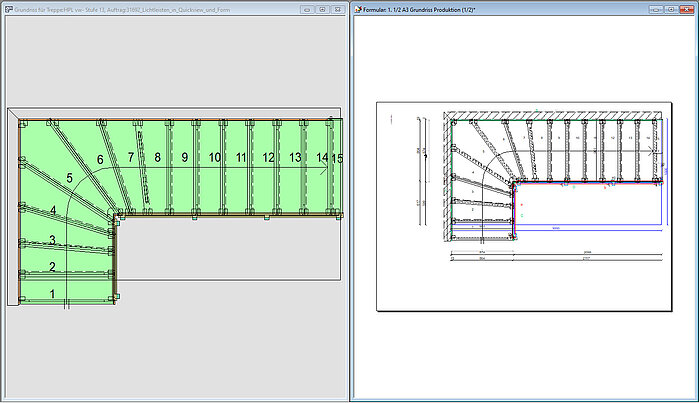

Forms: Quickview Light Strips

The display of the LED strips was missing in the quick view and in the forms. This has been extended accordingly.

- LED strips are displayed in the quick view of the staircase from the order tree

- If the electrical parts are activated in the floor plan form, the LED strips are displayed in the form.

Note: Already existing constructions must be opened and saved once again without being changed. Only then, the information will be available in the quick view and the forms.

CAM/CNC

Plate Optimization 2.0

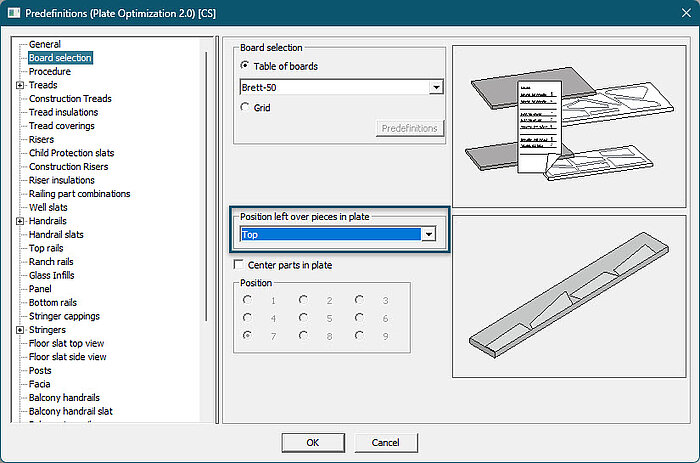

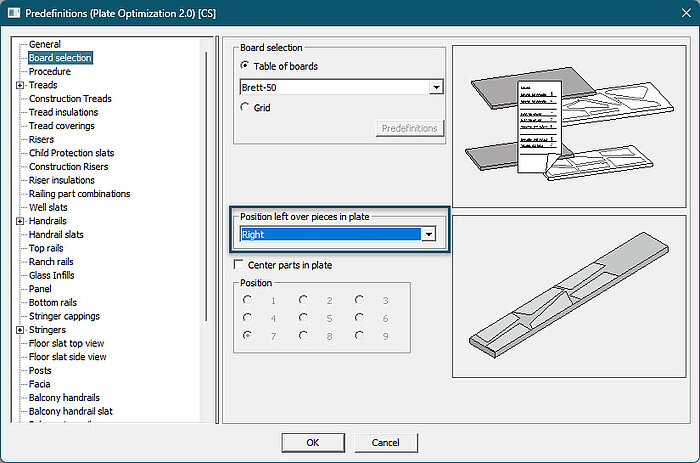

Right used to be the default and is now pre-selected via the checkbox--> Leftover pieces under 1m on the last nesting plate were often difficult to recycle and then accumulated in workshop corners or were even disposed of as firewood. Top was added because it makes sense to keep the long lamella and glue 2-4 long lamellas together to form a new panel.

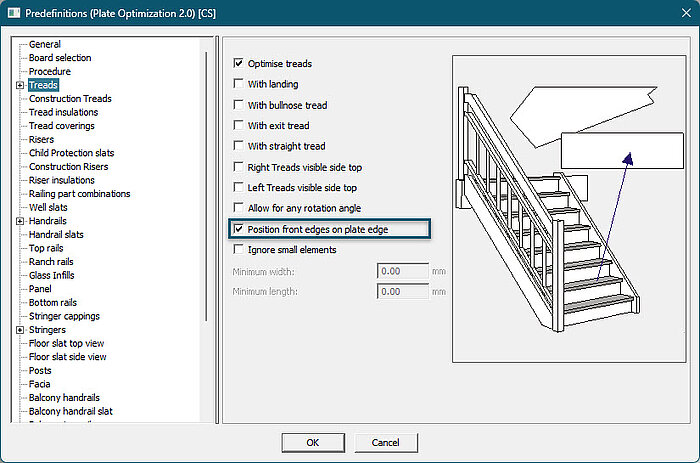

New switch to position the front edges of the tread to the edge. The preset distance to the edge is taken into account. This ensures that the first wood lamella in the tread is always the same size. If the distance is set to 0 mm, a finished edge with profile/postforming edge/edge banding can also be processed at the machine stop.

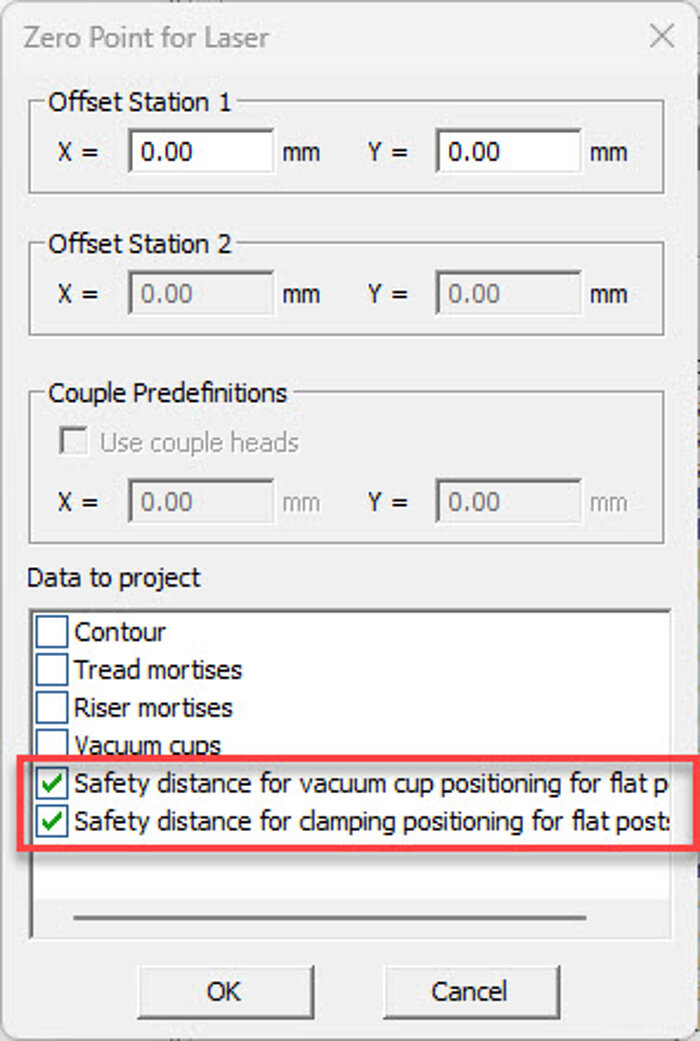

Drillings Going Through for Laser Images of Treads

Drillings going through can be activated in the settings for the laser image of treads.

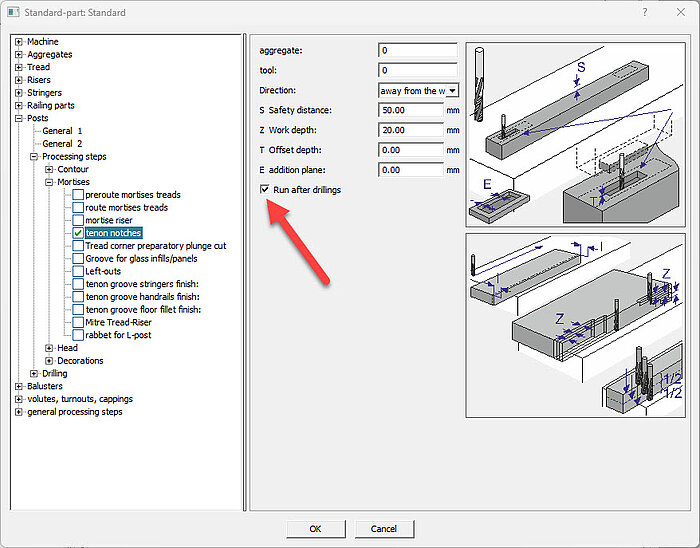

New feature: Tenon Notches in Posts

New feature: Tenon notches in posts are made after all drillings which belong to this clamping.

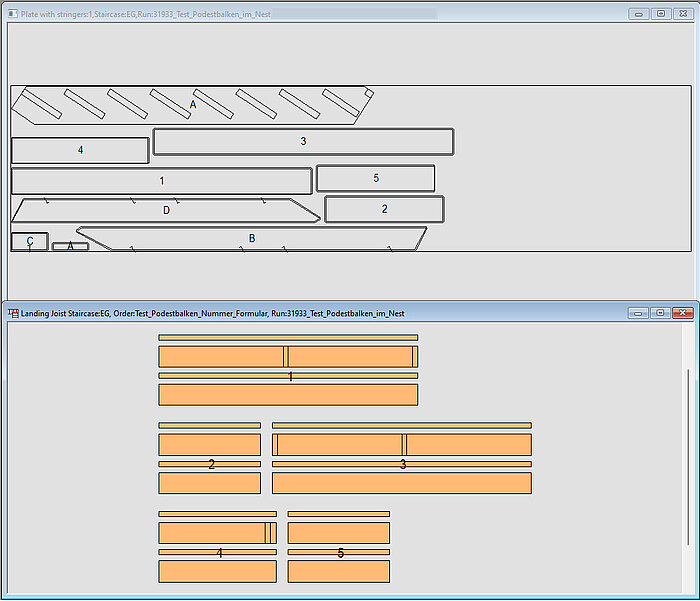

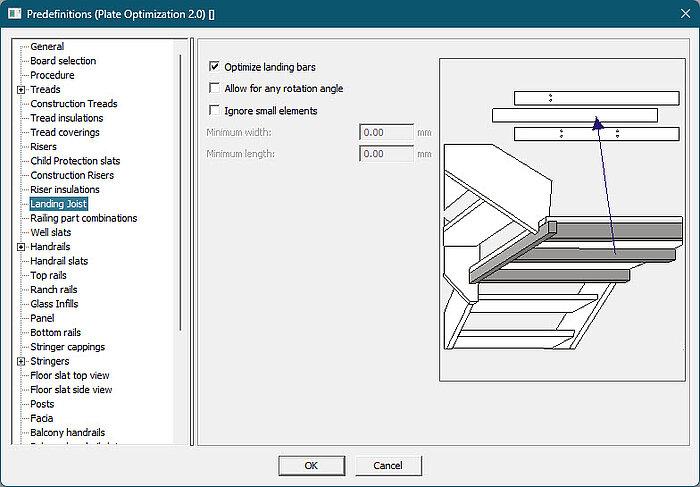

Plate Optimization 2.0: Landing Joist Nesting

Landing joists can also be optimised in the Plate Optimisation 2.0 if the article 00313202 - Option CAM/CNC Landing joist machining is included in the software package.

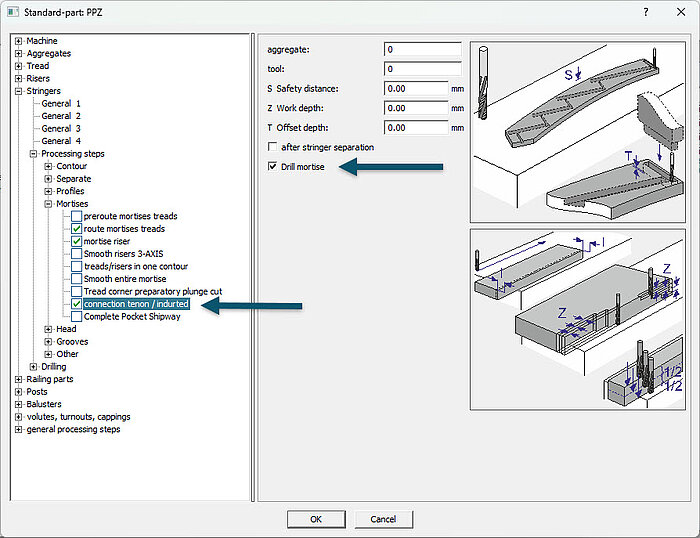

“Connection Tenon / Mortised” Operation with Precutting for Stringers

It is now possible to use pre-cutting for the " Connection Tenon / Mortised " stringer operation.

Pre-cutting prevents tearing when the operation is performed after the contour.

To enable pre-cutting, check the appropriate box in the operation (see screenshot). During program creation, the defined tool will be used to pre-cut to the required depth.

Laser Image for Posts

The laser image for a three-side-processing can be generated for posts.

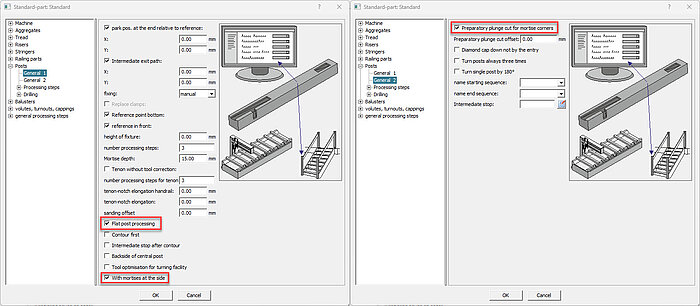

Preparatory plunge from the side in the flat post processing

Preparatory plunge cuts for mortise corners can now be processed from the side in the flat post processing.