General

External Stair: Copy Risers

In the external staircase, there was a "copy" function in the order tree on the individual treads. This was not previously requested for the risers. At the request of a customer, this feature has been added to the risers as well.

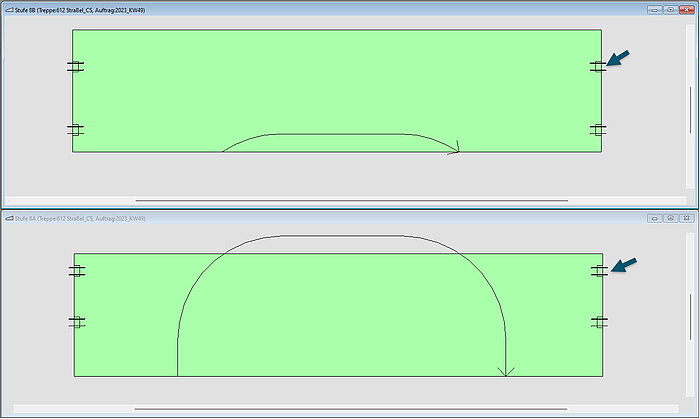

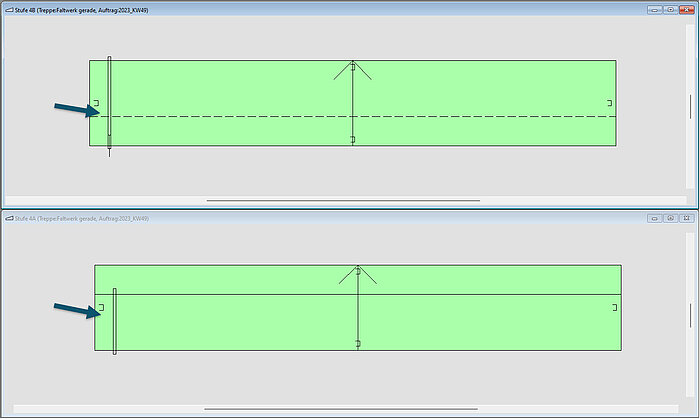

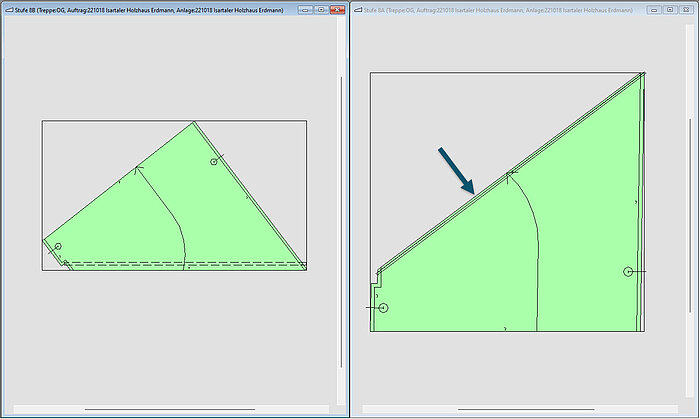

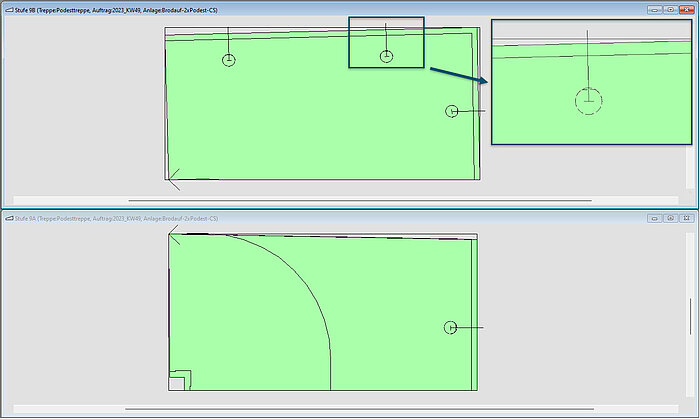

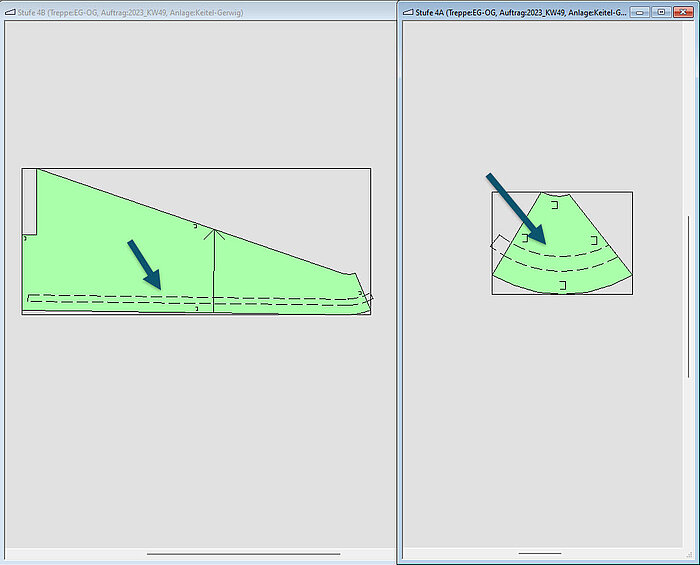

“Split” Landings and Treads in the Order Tree

Treads and landings can be split into two or more parts in the order tree using the "Split" function.Previously, some operations were not considered in the "split" function. Due to the increasing number of customer requests in this area, we have collected the open requests and revised the function.

The following functions have been updated:

- The riser grooves on the rear edges of the treads remain intact after cutting.

- The glass grooves in the top edges of the treads remain intact after cutting.

- Pockets on double angles remain intact after cutting.

- Riser grooves in arches remain intact after cutting.

- The flattened pockets of the clamping screw remain intact after cutting.

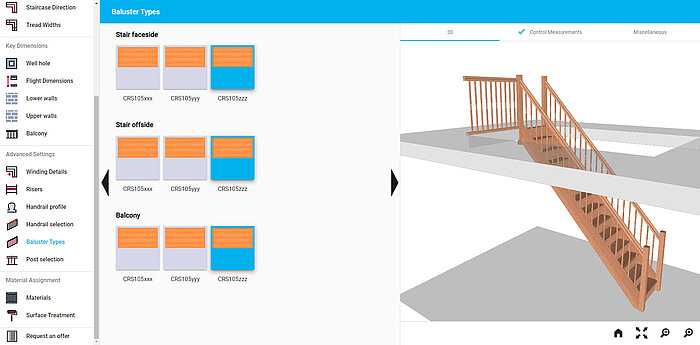

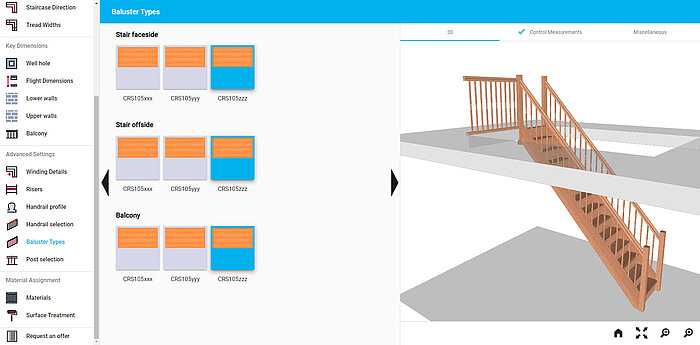

Balcony Railing Balusters in Online Configurator

In the initial online calculation, the balcony is now calculated using the standard baluster specified for the staircase. Previously, in the Stair Configurator, as in the offline system, the baluster type came from the balcony predefinition. This was often different from what was required online.

Online, the baluster type defined by default in the Stair Configurator administration is now used in the initial calculation of the balcony balustrade.

It is now possible to change the baluster types separately in the railings.

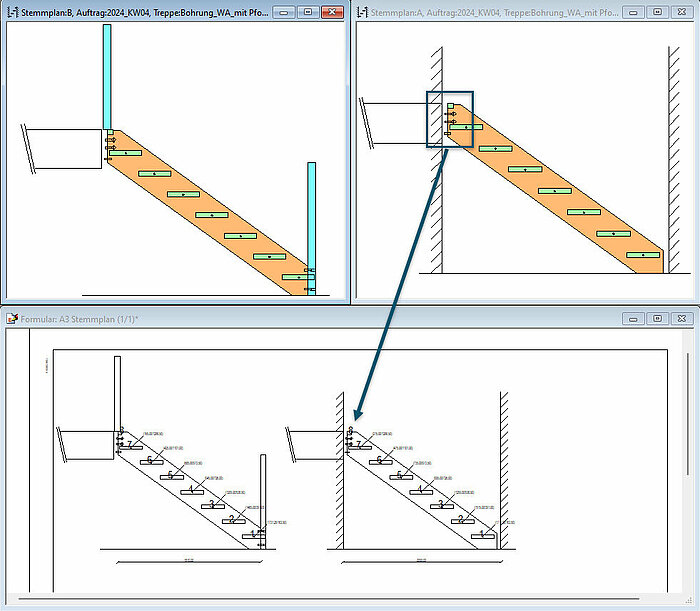

CAD Design

Drilling Pattern Stringer Wall/Ceiling

The front is now transferred into the displays in the tree of orders and the form mortising plans.

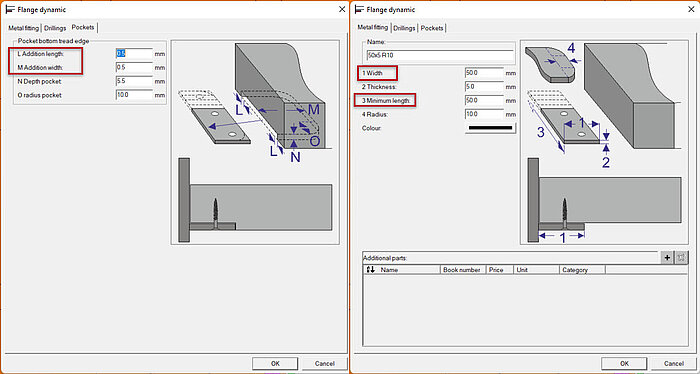

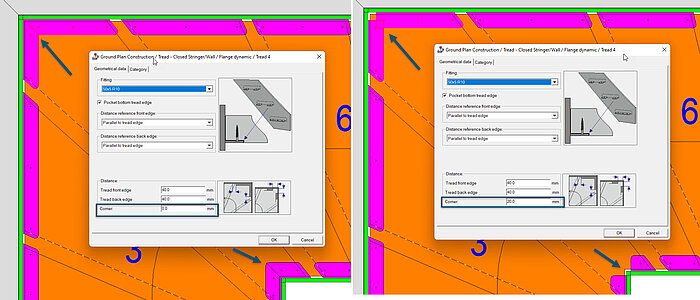

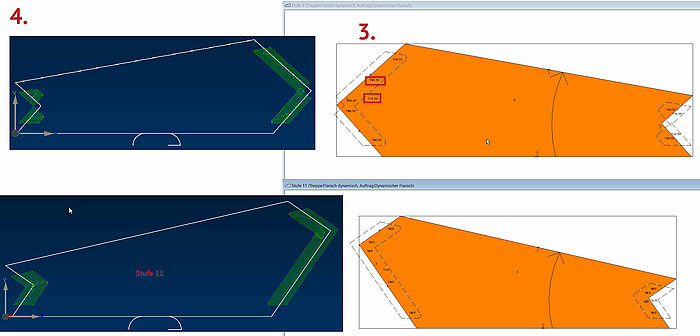

Dynamic Flange

The dynamic flange has been modified and optimized as part of the expansion.

- The parameters for the pocket settings have been corrected, length is width, width is length and it is possible to work with additions.

- In the outside or inside corners, only the distance to the corner is taken into account; if zero, a miter is calculated; if greater than zero, 90° is output.

- For the pockets in the tread, the additions from the dialog are taken into account.

- If possible, the pockets in the template are combined into one pocket.

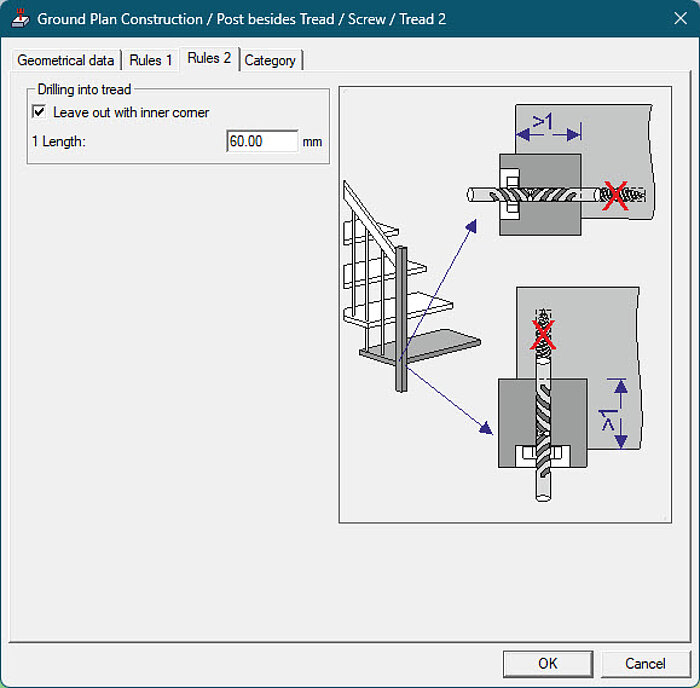

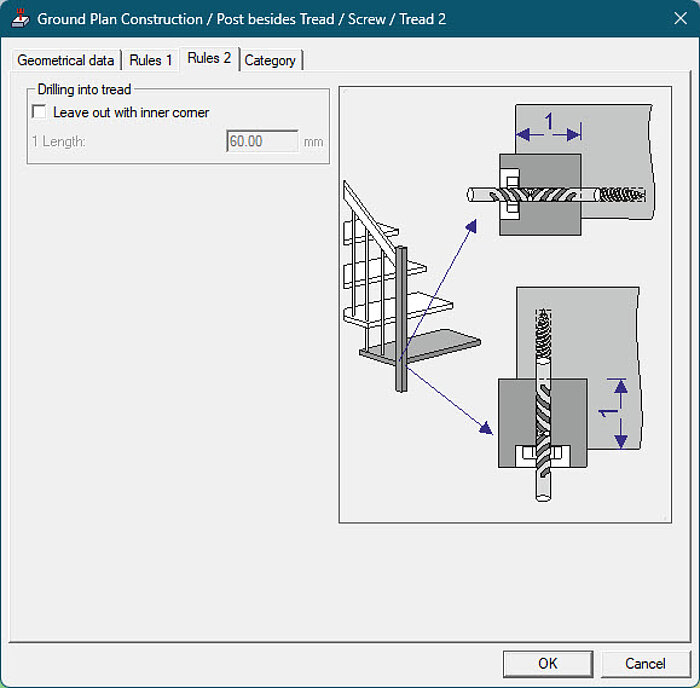

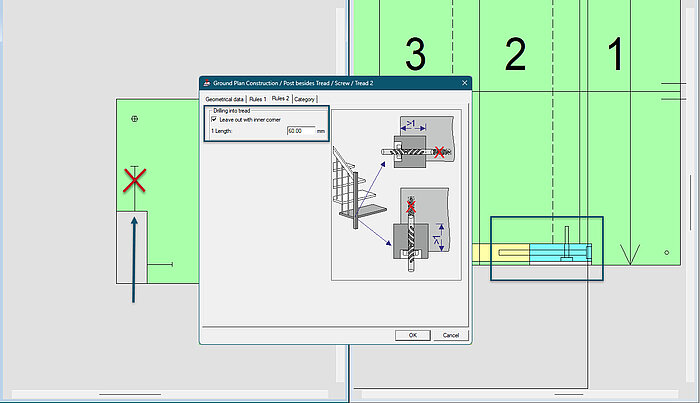

Drilling Pattern Post besides Tread

A rule has been added to the drilling pattern post besides tread. It is now possible to suppress drilling in the tread template. The length of the inside corner that causes the post in the template is checked. If this corner is longer in the drilling direction than the set value, the drilling in the tread is suppressed and must be done manually. The post drilling remains in the desired position.

Application: e.g. the flat post of a handrail-supporting bolted staircase as shown in the picture below. Standard dimensions approx. 160x45 mm. This post is connected to the tread with thick, long system screws. The system screws must be pre-drilled.

Problem solved: The drilling depth and the length of the inside corner, which can vary depending on the system and structural conditions, cause problems with the tool length. If the drill bit is too short, the tool holder or even the power unit will move into the edge of the material during drilling. The material is broken and in some cases the tool and machine are damaged. This can now be prevented, justifying the extra effort for the customer to drill the hole in the tread by hand.

CAM/CNC

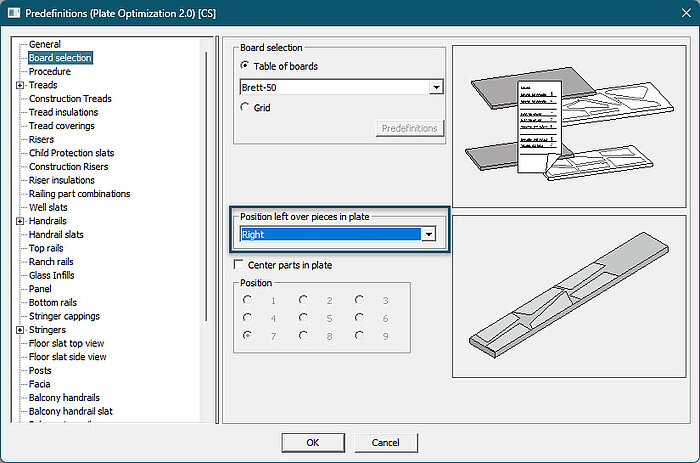

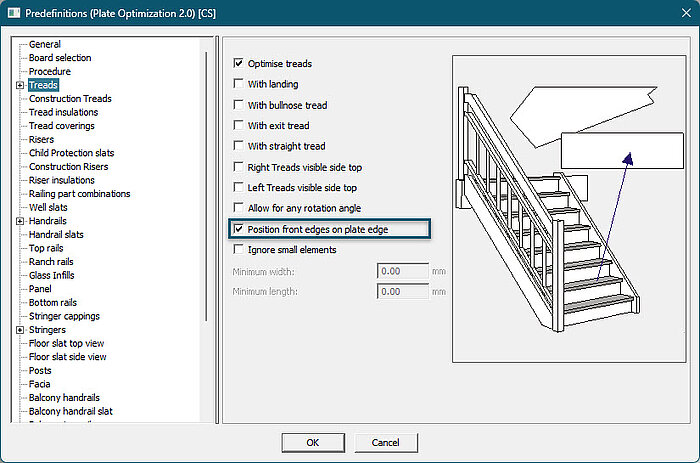

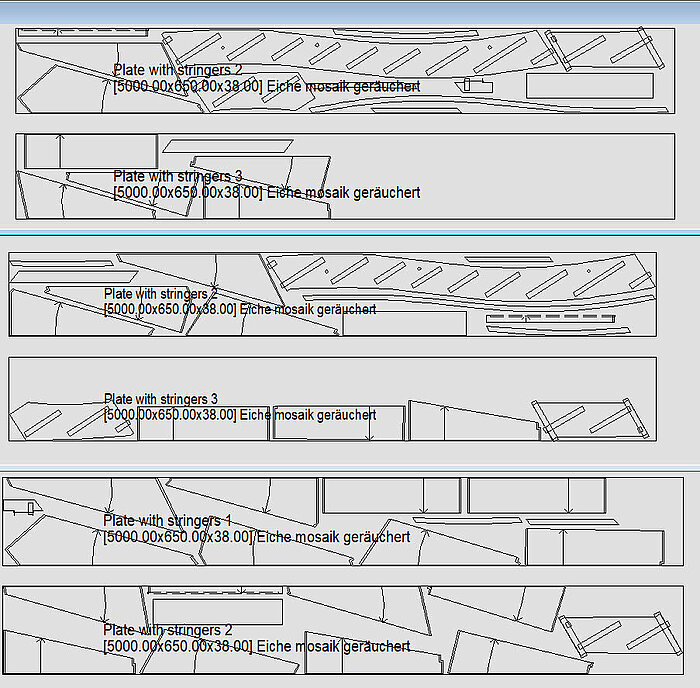

Plate Optimization 2.0

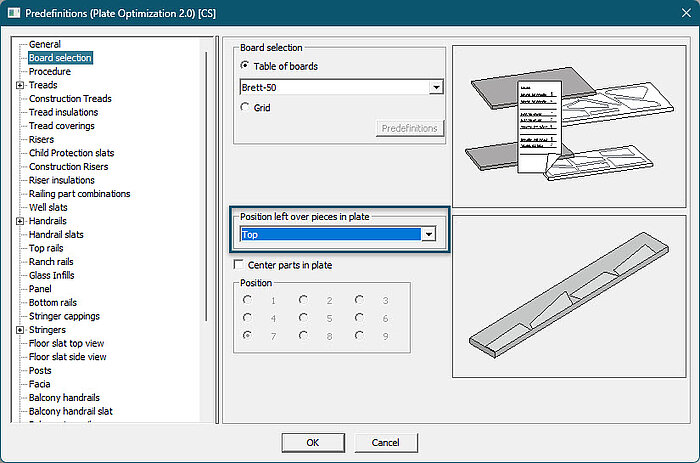

Right used to be the default and is now pre-selected via the checkbox--> Leftover pieces under 1m on the last nesting plate were often difficult to recycle and then accumulated in workshop corners or were even disposed of as firewood. Top was added because it makes sense to keep the long lamella and glue 2-4 long lamellas together to form a new panel.

New switch to position the front edges of the tread to the edge. The preset distance to the edge is taken into account. This ensures that the first wood lamella in the tread is always the same size. If the distance is set to 0 mm, a finished edge with profile/postforming edge/edge banding can also be processed at the machine stop.