Software from Planning to Manufacturing

Manufacturing is one of the central building blocks of our software.

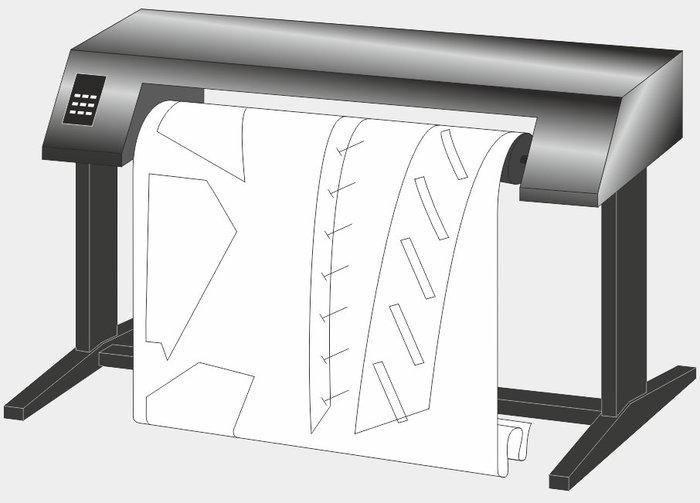

Manufacturing is integrated into our stair building solution and seamlessly follows the CAD module. Manual production with templates is possible, as well as automated processing with CNC machines. Compass Software supports all machines from established manufacturers. This also includes special machinery and old machines.

Next to our CAD/CAM complete solution for stair manufacturing, Compass Software's CAM solution also offers connections to various CNC machines in other construction areas, e.g. timber construction. All established machines can be connected effortlessly. The general CAM solution is based on different interfaces with a neutral processor. This makes it possible to utilize the module for all CNC machines on the market. Furthermore, the software offers lucrative expansion options for plate optimization, production management and control, as well as the connection of robots for the unmanned loading of CNC processing centers.

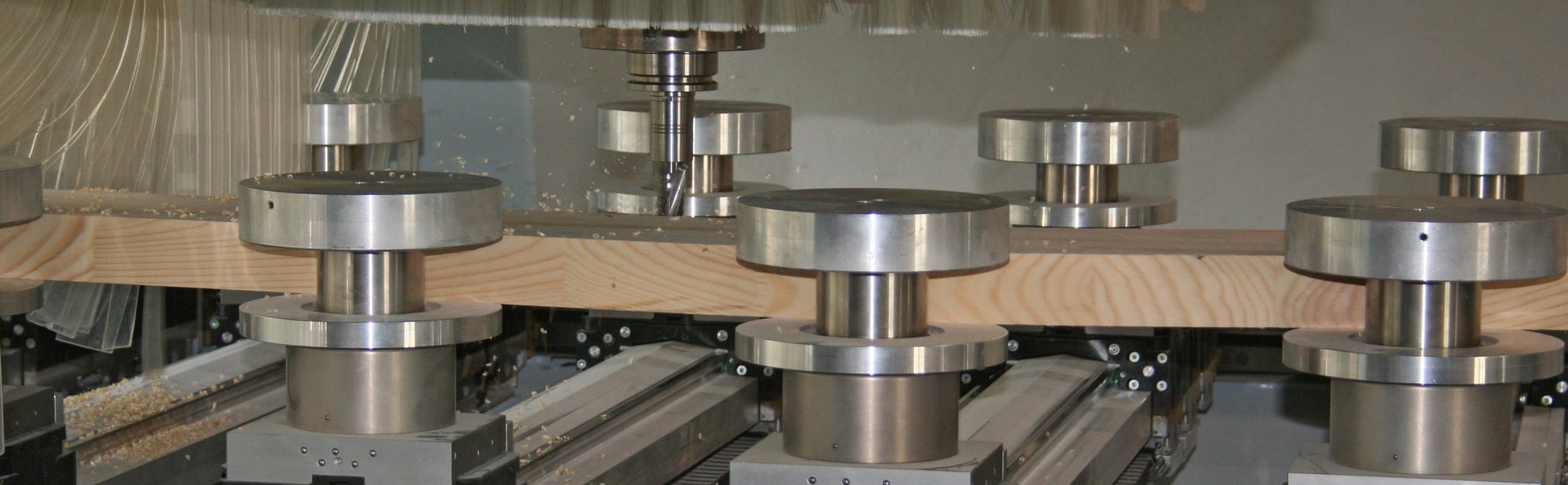

Clamping Device Calculation

We also offer full management for automatic calculations of clamping device positions - these include vacuum cups or horizontal/vertical clamps. It is even possible to move or reclamp parts in between processing steps (given that the machine allows for this to happen).

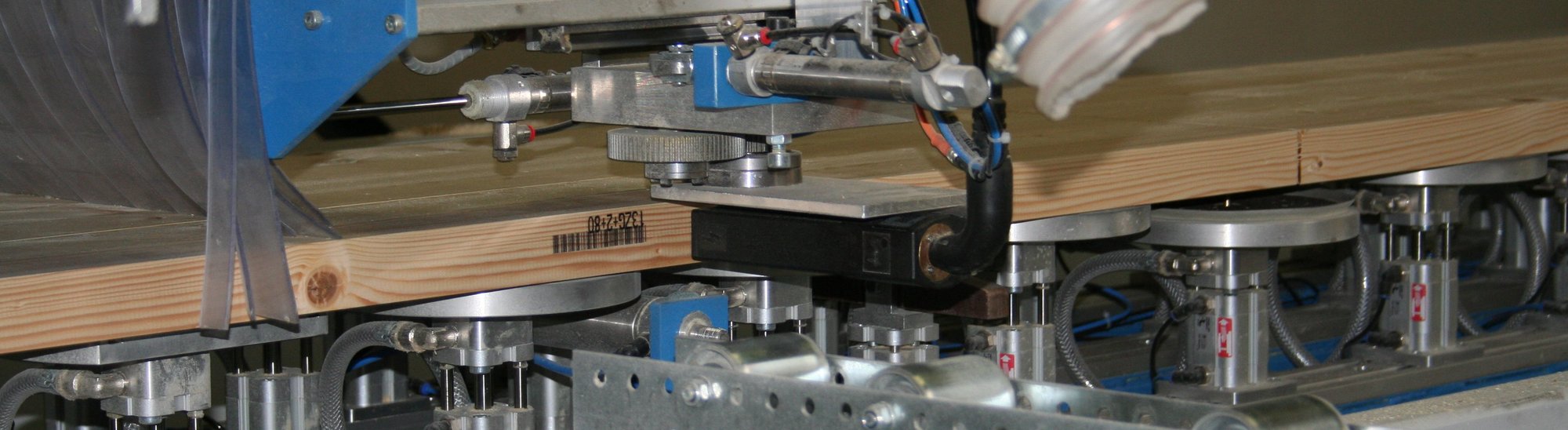

Barcode, Choice of Station, and Table Arrangement

Professional manufacturing in the 21. century is supported by communication systems that are based on the utilization of barcodes, RFID-chips, or similar marking systems.

Compass Software offers a system that is completely integrated into the manufacturing process for this method as well. The system is especially helpful for smaller companies, who use it to optimally manage data flow between job preparation and manufacturing.

Further possibilities to increase efficiency are barcodes in combination with choice of station or table arrangement via barcodes.

These methods make processes on all stations within the work shop significantly more effective and avoid errors.

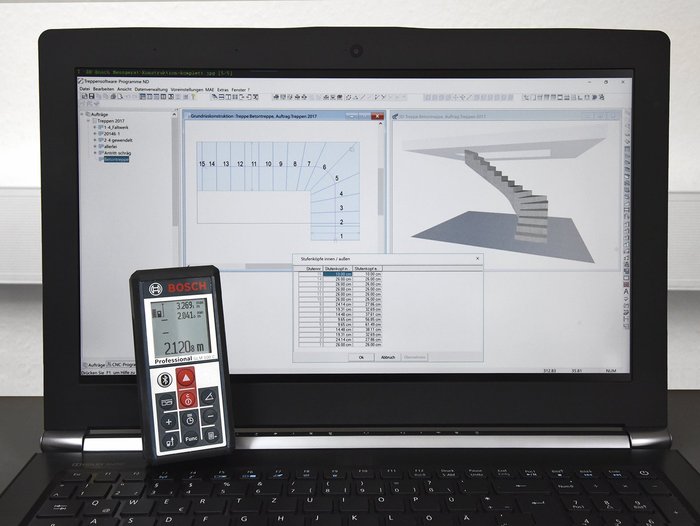

Laser Measurement Systems for Stair Manufacturing

The demands for modern stair builders are becoming more complex every day. Carpenters have to deal with the most complicated objects in some cases since modern architecture is breaking all the rules when it comes to creativity. A good stair manufacturing software is indispensable for the planning and manufacturing of such pieces of art.

The situation the carpenter is faced with at the construction site has to be measured precisely and oftentimes transferred painstakingly by hand into the CAD/CAM software. All relevant measurements, angles, roundings, and height differences have to be written down individually and entered into the design software in order to create the current construction site situation as a planning guide.

Modern 3D laser measurement systems make this process significantly easier, however, they still require manual transfer of data in most cases, since the automatic synchronization of measurements does not always work smoothly with many processing software. And this is precisely the point where Compass Software comes into play and offers fully integrated interfaces to different systems.

Precise digital 3D measurements, a complete interface to the design software, and the seamless transfer of production data to the CNC, which includes nesting, makes the successful completion of every project possible.