These solutions help save time and reduce errors by clearly identifying all parts.

Have you seen our component identification and label printing solutions

These solutions help save time and reduce errors by clearly identifying all parts.

With the 'Print labels in barcode window' option, labels can be printed directly from the barcode dialogue box when creating the CNC program. This speeds up the production process and each part remains uniquely identifiable until completion. This saves time and minimises errors - no part is lost.

Labels are particularly valuable in the nesting process: when all components of a large panel need to be labelled, our solution ensures that the position of each component is clearly marked.

The operator can use a touch screen dialogue to determine the exact position of the label to ensure correct placement. All label content is freely configurable and can be customised.

Compass Software enables fully automatic labelling, e.g. with a labelling machine. The software automatically calculates the label positions and, together with the CNC codes, provides all the data to control the labelling station. The operator does not have to do any extra work - everything runs automatically. The labels are positioned in such a way that they will not be damaged during subsequent CNC processing, e.g. mortising, drilling, pocketing etc., where possible.

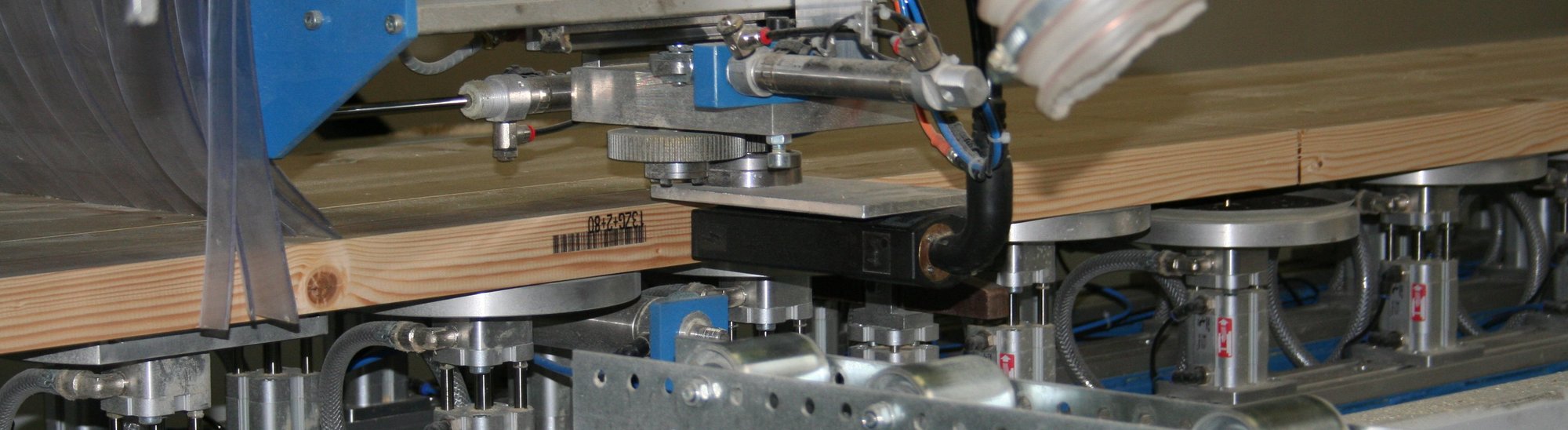

Another highlight of our solutions is the control of an inkjet printer, which prints part information in clear text directly onto the components. The process works on a queuing principle: as soon as a part has been machined on a CNC machine, it is transferred to the labelling station. Information about the next part in the production queue automatically appears on a screen. The operator only needs to hold the finished part briefly in front of the printer and trigger the printing process with a foot switch. By seamlessly integrating labelling into the production flow, no part is left unlabelled.

Curious about more efficient component marking?

Contact us to find out more about the possibilities of labelling with Compass Software!