Overview of the main benefits:

- Material savings: Up to 20% for standard staircases and 10-15% for complex, exclusive staircases.

- Labour savings: From 3 to 1.5 operators for the machine.

- Increase in turnover: Planned increase of up to 60% with two-shift operation.

- Time savings: Parallel machining on two CNC machines during the nesting process.

- Safer working conditions: Minimised physical strain on operators thanks to automated transport of heavy panels.

- Reliable implementation: Compass software worked flawlessly from day one.

- Excellent support: Quick response to support requests and local service partner in Norway.

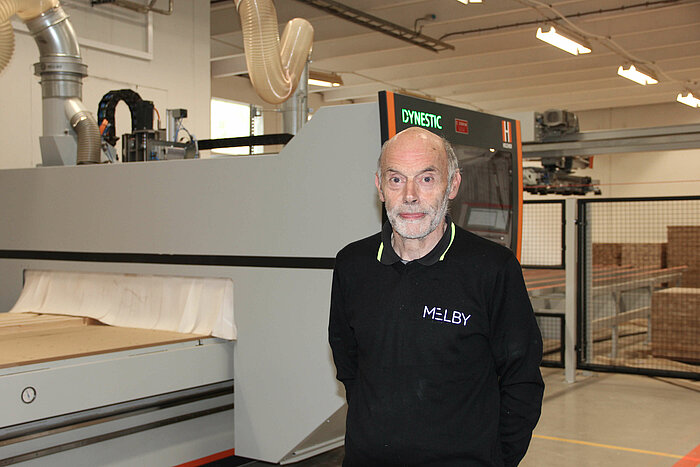

Melby Treppenbau - A success story since 1952

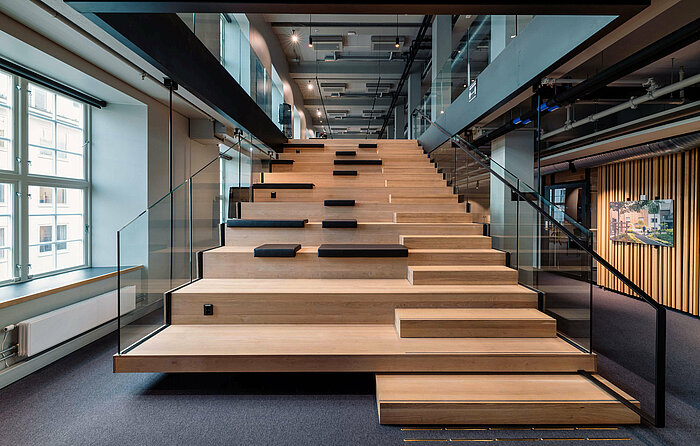

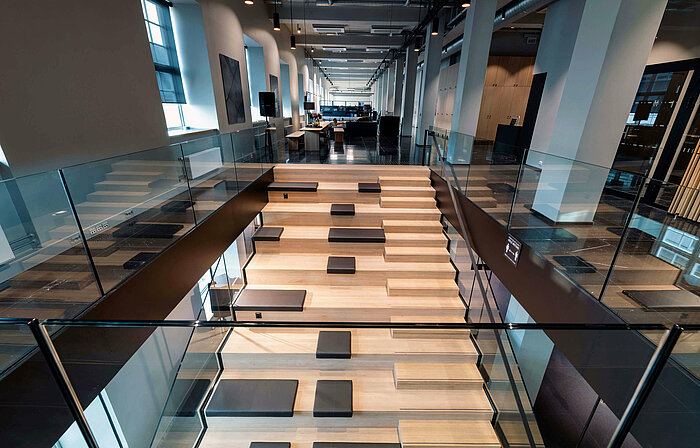

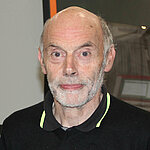

Melby Treppenbau was founded in 1952 by Bjørn Melby's father as a small joinery. In the beginning, the main focus was on the production of windows, doors and kitchen furniture. In the 1960s the company specialised in the construction of stairs. Since 1980, Bjørn Melby has been at the helm of the company, which now employs 20 people and specialises in the production of exclusive, custom-made staircases. "Our staircases are not only functional, but feature many individual details and the highest quality, which makes them unique,' says Melby proudly.

With the purchase of CNC machines in the 1990s and the continuous upgrading of its machinery, Melby invested early in modern production technology. Since 2011, the company has relied on Compass Software to further optimise its production. Previously, the company used the Wagemeyer staircase software, but over time it was no longer able to meet all the staircase manufacturer's requirements. After a long search and many recommendations, the company found the ideal partner in Compass Software.

Download Case Study as PDF

I am still convinced that there is no better stair design and manufacturing software than Compass Software

Bjørn Melby - Owner

Innovative technology: The nesting station and the automated warehouse

One of the most recent and important technological advances at Melby Stairs is the introduction of a HolzHer DYNESTIC 7535R nesting machine with a connected HolzHer Store Master automatic storage system. The introduction of this technology has fundamentally changed the production processes. The Compass Software module Panel Optimisation 2.0 helps the stairbuilder to determine the exact size of the required panels from the warehouse. They are then automatically transferred via crane from the warehouse to the machine. Once there, Compass Software is used to optimise the processing and utilisation of the panels. Approximately half of all parts can be completely finished on the nesting machine.

"In the past, our employees had to manually transport and load the heavy panels, which was very physically demanding," explains Bjørn Melby. Today, the automatic crane in the plate storage area does the job, making the process not only more efficient but also safer.

Another advantage is that the machine operator can perform other tasks while parts are being processed on the nesting machine, such as operating the adjacent 5-axis CNC machine. This means that 2 machines can be operated simultaneously by just one person.

Significant savings and efficiency gains

The introduction of nesting technology has not only reduced the amount of labour required at Melby, but has also resulted in significant savings. By optimising material utilisation, the company saves an average of 10 - 15% on material and up to 20% on the production of standard staircases. These savings have a direct impact on production costs, enabling the company to offer competitive prices without compromising on quality.

"The material savings are only part of the success," stresses Melby. "We have also been able to reduce the number of people working on the machine from 3 to 1.5." This allows the company to use the freed-up manpower in other areas of production, resulting in greater flexibility and productivity. By using the nesting machine, Melby has gained valuable time that can be invested in other jobs.

We were able to reduce the number of people working on the machine from 3 to 1.5. Next year, we are planning to move to two shifts. This will allow us to increase our sales by up to 60 per cent and meet the growing demand in the market.

Bjørn Melby - Owner

Reliable implementation and ongoing support

The smooth implementation of the new technology was crucial to the success of the new process. “With Compass Software, the nesting machine worked perfectly from day one," says Melby. By comparison, a friend of Melby's who owns a staircase company and installed the same system with another software supplier took several months to become fully operational.

In addition to the reliable implementation, Melby also appreciates Compass Software's excellent customer service. “Support is always available and our questions are answered quickly and competently," says Melby. He particularly emphasises the fact that Compass Software also has a local partner in Norway who can advise in the local language and provide on-site support in the event of problems.

With Compass Software, the nesting machine worked perfectly from day one

Bjørn Melby - Besitzer

Market advantage with Compass Software

For Melby Stairs, working with Compass Software is not only a solution to the daily challenges of production, but also a decisive competitive advantage. “Compass Software is recognised as the market leader in the industry and this gives us the confidence that we are always using the best technical options available," says Melby. He is particularly impressed by the ongoing development of the software to meet the needs of the market. “Our customers' requirements are becoming more and more individual and Compass Software enables us to meet these needs.”

For the staircase manufacturer, Compass Software is more than just a software solution - it is a strategic partner that is taking the company into the future. By investing in nesting technology and working with Compass Software for many years, Melby has been able to optimise its production processes, realise material and time savings, and create the basis for future growth. “We are convinced that Compass Software will continue to support us in strengthening our position as the leading stair manufacturer in Norway," concludes Bjørn Melby.